In the modern food processing industry, hygiene, safety, and efficiency are the top priorities for businesses. Plastic sheets have become indispensable in food processing equipment and factory construction due to their lightweight, corrosion resistance, easy cleaning, and customizable properties. This article explores the main applications of plastic sheets in the food industry and the related safety standards, helping companies enhance production efficiency while ensuring food safety.

Plastic sheets in direct or indirect contact with food must meet strict safety standards. Common regulations include:

1.FDA (U.S. Food and Drug Administration) Standards: Ensure materials do not transfer harmful substances to food.

2.EU 10/2011 (EU Food Contact Materials Regulation): Sets limits on migration for plastics that come into direct contact with food.

3.ISO 22000 & HACCP Systems: Emphasize food safety management throughout the production chain, requiring plastic sheets to be easy to clean and resistant to microbial growth.

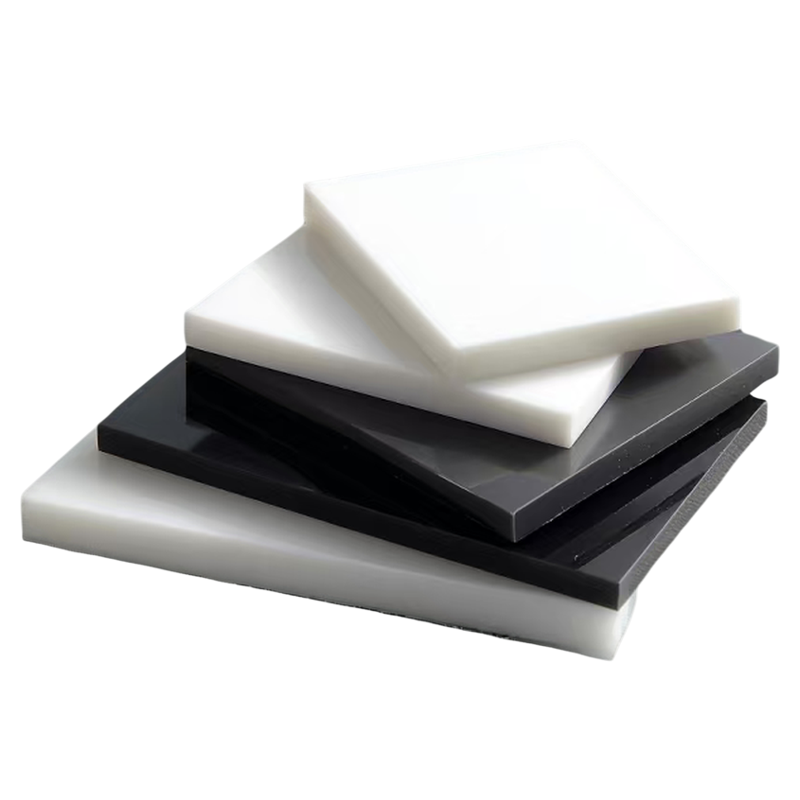

2.Common Plastic Sheets in Food Processing

HDPE (High-Density Polyethylene): Chemical-resistant, easy to clean; ideal for cutting boards, conveyors, and storage containers.

PP (Polypropylene): Heat-resistant; suitable for steaming and hot-fill food processing environments.

PETG (Polyethylene Terephthalate Glycol): High transparency; suitable for visual inspection applications and partition panels.

PVC Food-Grade Sheets: Tough and impact-resistant; commonly used as protective panels and machine guards.

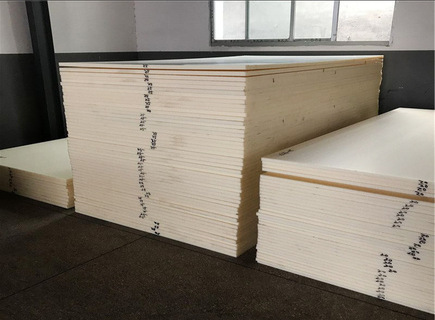

3.Key Application Scenarios

Cutting and Processing Surfaces: Smooth, wear-resistant, prevents food from sticking, easy to clean and sanitize.

Conveyors and Dividers: Water and corrosion-resistant, preventing contamination during transportation.

Storage and Packaging Containers: Food-safe, prevents harmful substance migration, preserves original taste.

Equipment Protection & Factory Interiors: Chemically resistant; used in protective panels, walls, and partitions to extend equipment life and meet hygiene requirements.

4.Cleaning and Maintenance Guidelines

Clean daily with warm water and neutral detergent; avoid strong acids or bases.

Regularly inspect surfaces for scratches or damage to prevent bacterial growth.

For long-term use, consider high-temperature sterilization or FDA-approved sanitization methods.

5.Customers Focus On

1.Material Source & Safety Certifications: Ensuring raw materials are free from harmful additives and meet FDA or EU standards.

2.Ease of Cleaning & Antimicrobial Properties: Reducing cross-contamination risks.

3.Durability & Long-Term Cost: High wear, impact, and chemical resistance to minimize replacement frequency.

Thanks to their excellent physical properties, hygienic characteristics, and versatile applications, plastic sheets have become an ideal choice for enhancing safety and efficiency in the food processing industry. Choosing the right food-grade plastic sheets helps companies maintain high standards and meet stringent international market requirements.