When it comes to choosing the right plastic sheet for your project or industry application, understanding the basics of thickness, color, and processing methods is essential. Each of these factors not only affects the appearance of the material but also its performance, durability, and cost-efficiency. This guide will walk you through the fundamentals to help you make informed decisions.

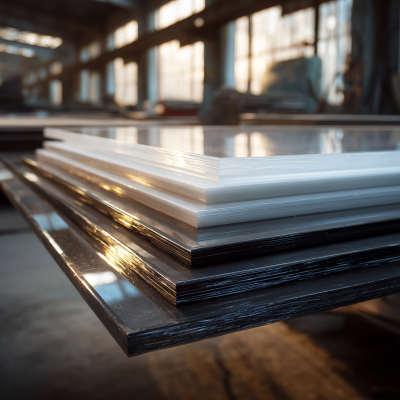

1.Thickness: Strength and Application Needs

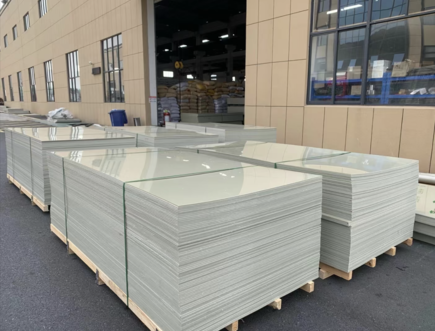

Plastic sheets are available in a wide range of thicknesses, from ultra-thin films to heavy-duty panels.

1.Thin sheets (1–3mm): Lightweight and flexible, often used for packaging, disposable covers, or lightweight displays.

2.Medium sheets (4–10mm): A balance of strength and flexibility, suitable for industrial panels, protective covers, and general-purpose use.

3.Thick sheets (10mm+): High rigidity and load-bearing capacity, widely applied in construction, structural components, tanks, and heavy-duty industrial equipment.

👉 Tip: The thicker the sheet, the stronger its mechanical properties, but weight and cost will also increase.

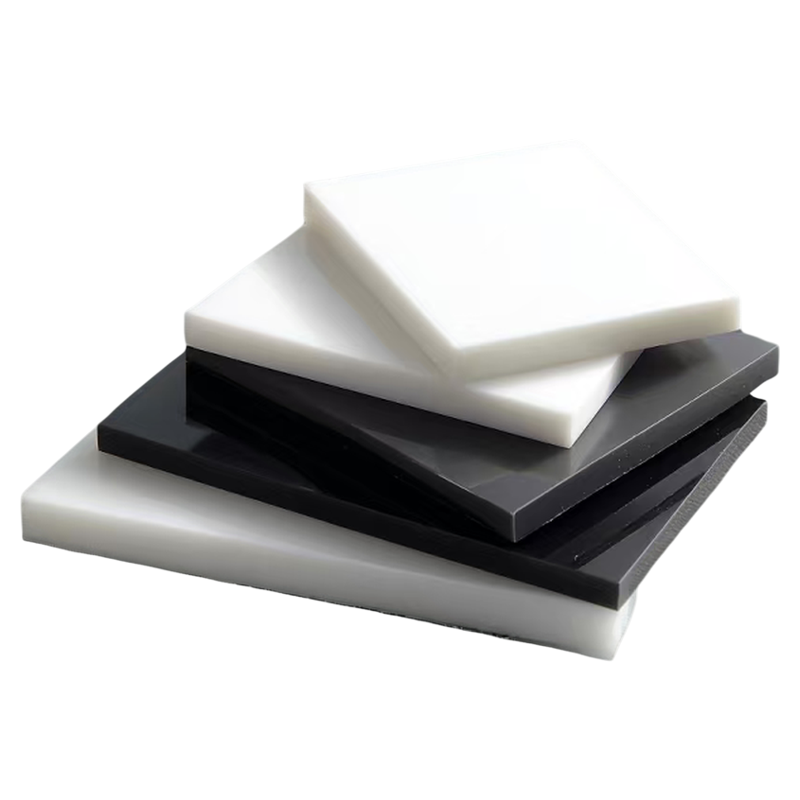

2.Color: Function Meets Aesthetics

Color isn’t just about looks—it also affects visibility, heat resistance, and brand identity.

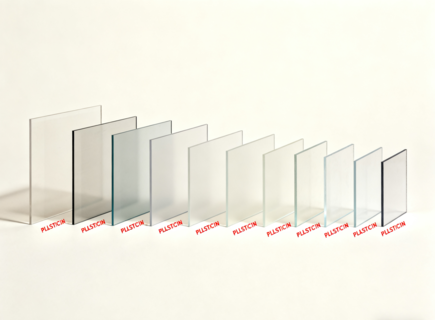

1.Transparent sheets: Provide clarity and visibility; ideal for displays, windows, safety shields, and packaging.

2.White sheets: Common in chemical and food industries thanks to their clean appearance and light-reflecting properties.

3.Black sheets: Excellent for UV resistance, hiding surface scratches, and providing a premium look in machinery and outdoor use.

4.Custom colors: Tailored solutions for branding, advertising, and decorative applications.

👉 Tip: If exposure to sunlight is expected, black or UV-stabilized sheets will last longer outdoors.

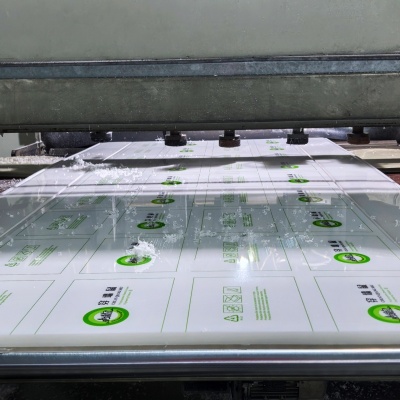

3.Processing Methods: From Raw Sheet to Final Product

The versatility of plastic sheets comes from the wide range of processing techniques available:

1.Cutting & CNC machining: Enables precision shaping for industrial parts, machine guards, and custom projects.

2.Thermoforming & bending: Allows sheets to be molded into 3D shapes, covers, or enclosures.

3.Welding & assembly: Used for constructing tanks, boxes, or large structural components.

4.Printing & surface finishing: Options like silk screen printing or UV printing add branding and identification.

👉 Tip: Always confirm whether your chosen plastic type (e.g., PP, PE, PC, PETG) is compatible with the processing method you need.

4.Choosing the Right Sheet for Your Project

When selecting plastic sheets, consider these key factors:

1.Environment: Will it be exposed to chemicals, sunlight, or low/high temperatures?

2.Mechanical strength: Does it need to withstand heavy loads, impacts, or abrasion?

3.Aesthetics: Do you require transparency, smooth surfaces, or customized colors?

4.Budget: Balance cost with durability and performance.

💡 Conclusion

Understanding the thickness, color, and processing methods of plastic sheets is the foundation for selecting the right material. Whether you need a lightweight PP sheet for chemical applications, a durable PE sheet for mechanical components, a transparent PC sheet for safety shields, or a versatile PETG sheet for displays and packaging—making an informed choice ensures better performance, lower costs, and longer-lasting results.

By knowing these basics, you can confidently choose the plastic sheet that fits your business needs and unlock the full potential of this versatile material.