Introduction: Why Plastic Sheet Recycling Matters

In today’s global push for sustainability, plastic sheet recycling has become one of the most critical topics across industries. From packaging to construction and automotive manufacturing, plastic sheets like PP, PE, PVC, PETG, and ABS are used extensively. However, the growing use also means growing waste.

Recycling these sheets not only reduces landfill pollution but also helps conserve raw materials and energy, making it a key part of the circular economy.

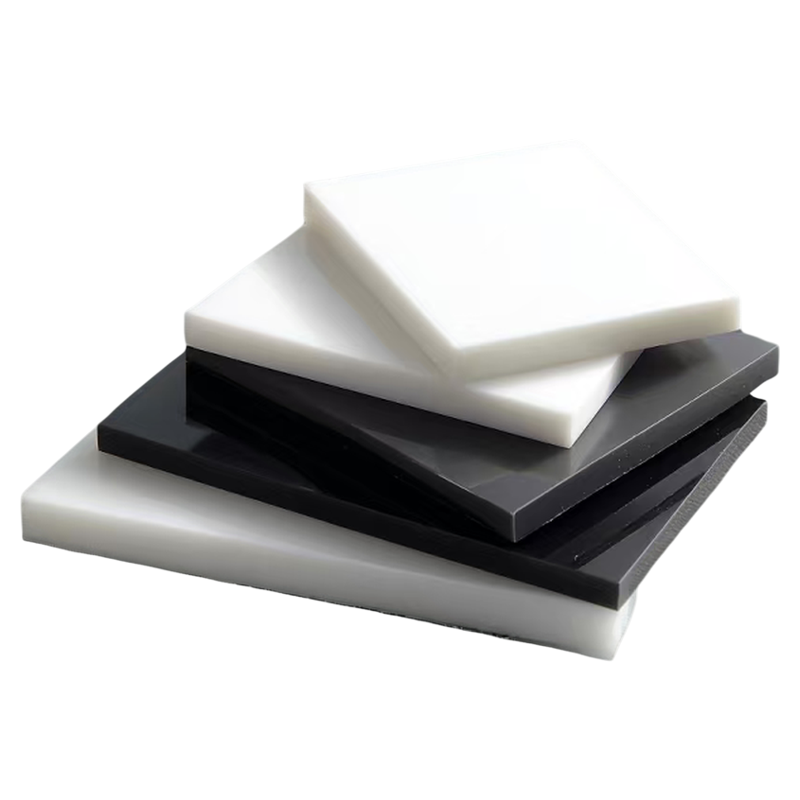

1.Types of Recyclable Plastic Sheets

Not all plastic sheets can be recycled in the same way. The most commonly recycled materials include:

1.PP (Polypropylene): Lightweight, impact-resistant, and easy to recycle for industrial reuse.

2.HDPE (High-Density Polyethylene): Commonly used for containers and tanks; can be shredded and reprocessed efficiently.

3.PETG (Polyethylene Terephthalate Glycol): Transparent and food-safe, ideal for recycling into packaging materials.

4.PVC (Polyvinyl Chloride): Requires special treatment due to chlorine content but can be recycled into pipes or panels.

5.ABS (Acrylonitrile Butadiene Styrene): Often used in automotive and electronics; can be melted and remolded for durable parts.

Each material requires specific recycling temperatures and purification steps to ensure quality reuse.

2.The Plastic Sheet Recycling Process

The process involves several key steps:

1.Collection and Sorting – Waste plastic sheets are collected from factories or post-consumer sources and sorted by type and color.

2.Cleaning and Shredding – Sheets are washed to remove dirt, adhesives, or oils, then shredded into flakes.

3.Melting and Extrusion – Clean flakes are melted and extruded into pellets.

4.Remanufacturing – These pellets are used to produce new plastic sheets or molded components.

Modern recycling systems use infrared scanners and AI-powered sorting machines to improve efficiency and reduce contamination.

3.Environmental and Economic Benefits

Recycling plastic sheets provides multiple advantages:

1.Environmental Protection: Reduces plastic waste and carbon emissions.

2.Resource Conservation: Less dependency on virgin resins made from petroleum.

3.Cost Efficiency: Recycled materials can reduce manufacturing costs.

4.Corporate Sustainability: Enhances brand reputation among eco-conscious customers.

Many global companies now require suppliers to use recycled or recyclable materials to meet ESG and carbon neutrality goals.

4.Challenges and Innovations in Recycling

While recycling brings benefits, it faces challenges such as:

1.Contamination and material mixing – makes reprocessing difficult.

2.Degradation after multiple cycles – mechanical recycling can lower strength or color quality.

3.High logistics costs – transporting bulky sheets can be expensive.

However, innovation is addressing these issues:

1.Chemical recycling breaks plastics down into monomers for near-infinite reuse.

2.Closed-loop systems within factories reduce waste during production.

3.Biodegradable additives are being developed for faster decomposition.

5.Future Trends: Toward a Circular Plastic Economy

The future of plastic sheet recycling lies in advanced materials and smarter systems:

1.Widespread use of 100% recycled plastic sheets in construction and packaging.

2.Digital traceability (QR-coded materials) to track plastic life cycles.

3.Governments promoting extended producer responsibility (EPR) programs.

As sustainability becomes a global standard, recyclable and eco-friendly plastic sheets will dominate industrial and consumer markets.

Conclusion

Plastic sheet recycling is more than an environmental act — it’s a business opportunity.

Companies that invest in recyclable design, green manufacturing, and closed-loop systems are not only reducing their carbon footprint but also building stronger, future-ready brands.

In a world where sustainability sells, recycling is no longer optional — it’s essential.