Introduction

In industrial plastics, plastic sheets and plastic rods are the two most common semi-finished products. Although they differ in shape, they share the same manufacturing roots and similar engineering properties. Understanding their relationship helps engineers and buyers choose materials more wisely.

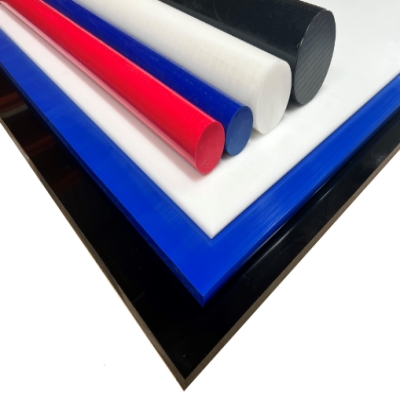

Both sheets and rods are made from the same thermoplastics — such as HDPE, PP, PVC, UHMW-PE, PTFE, and Nylon (PA6).

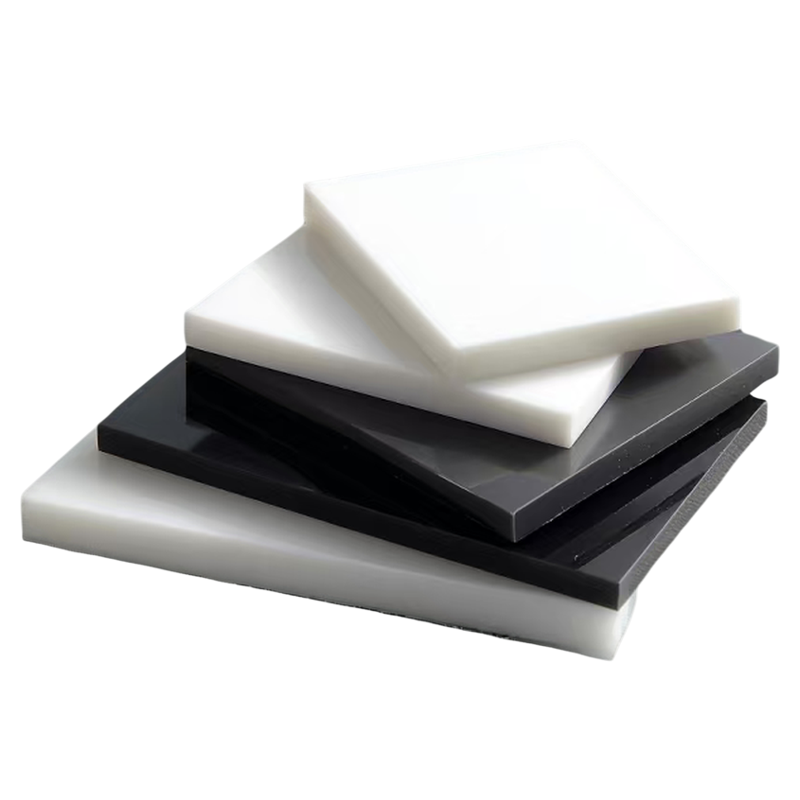

Sheets: flat, used for panels, linings, and covers.

Rods: cylindrical, ideal for machining small mechanical parts.

Despite their different shapes, they often share identical mechanical, thermal, and chemical properties.

2.Complementary Applications

Sheets and rods are often used together:

PP sheets build chemical tanks, PP rods weld fittings.

UHMW sheets serve as conveyor guides, UHMW rods as rollers.

Their synergy supports industries such as chemical processing, food equipment, marine structures, and machinery fabrication.

3.Machinability and Customization

Both forms are easy to cut, drill, or CNC machine.

Sheets: suitable for routing, thermoforming, welding.

Rods: ideal for turning, threading, and precision parts.

Foreign buyers value custom thickness, diameter, color, and additives (UV, flame retardant, anti-static).

4.Cost and Efficiency

Choosing between sheets and rods depends on project needs:

Need large surfaces → choose sheets.

Need small round components → choose rods.

Understanding this helps reduce waste and machining costs — a major factor for global buyers.

5.Sustainability and Recycling

Manufacturers now produce both sheets and rods using recycled materials, maintaining strength while reducing waste.

Recycling offcuts from both forms creates a closed-loop production system, aligning with global sustainability goals.

Conclusion

Plastic sheets and rods are not competitors but partners in modern manufacturing. Their shared materials and complementary roles make them vital for diverse industries. Knowing how they relate ensures smarter choices, lower costs, and longer-lasting performance.