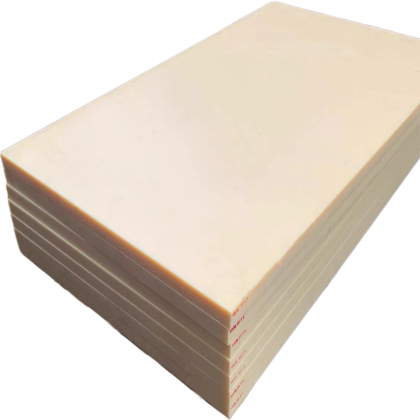

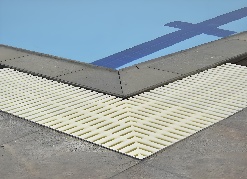

1.High Impact Resistance

ABS sheets are renowned for their exceptional toughness and ability to withstand impact, making them ideal for demanding applications.

2.Good Mechanical Strength

They provide excellent structural stability and rigidity, maintaining their shape under stress.

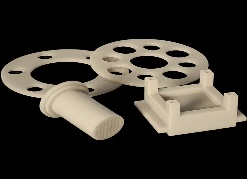

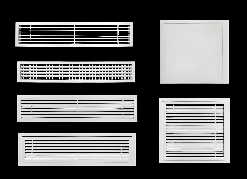

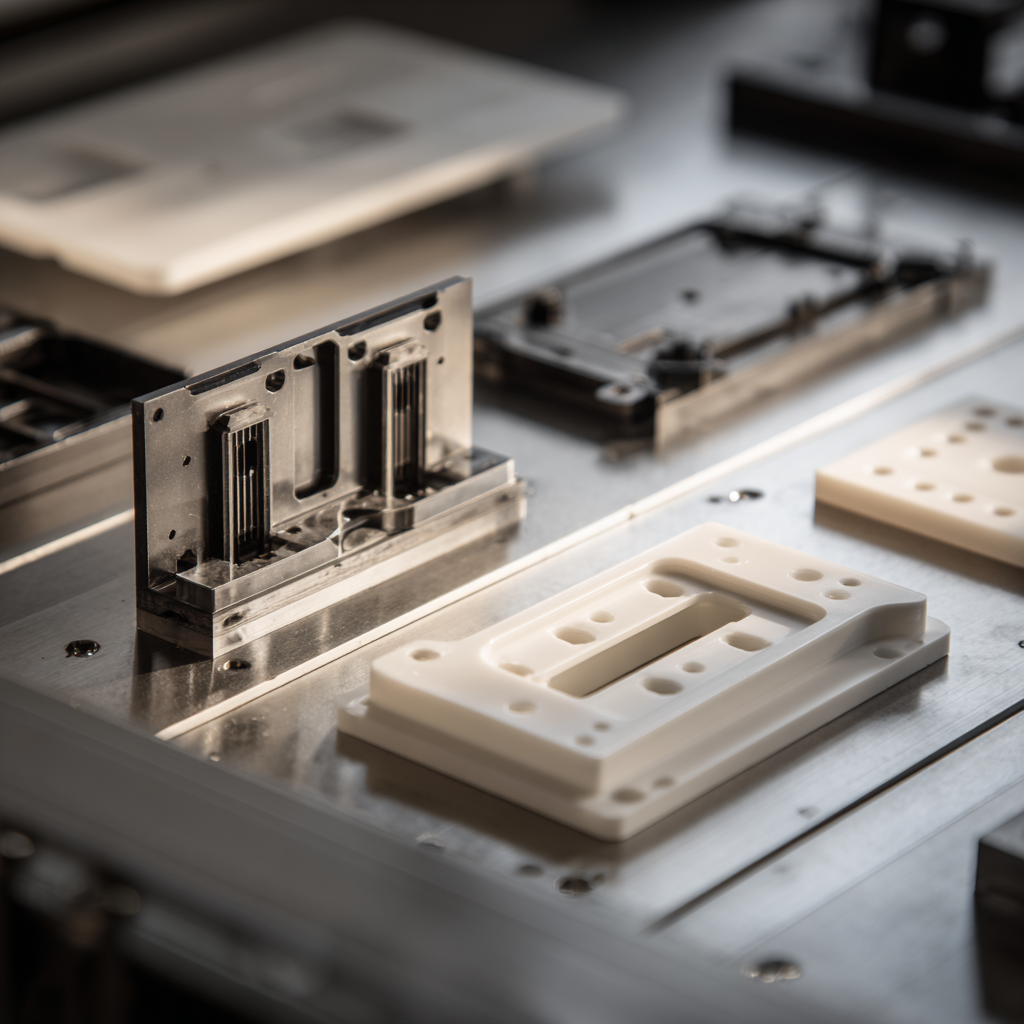

3.Excellent Machinability

ABS sheets can be easily cut, drilled, thermoformed, and fabricated into complex shapes without cracking.

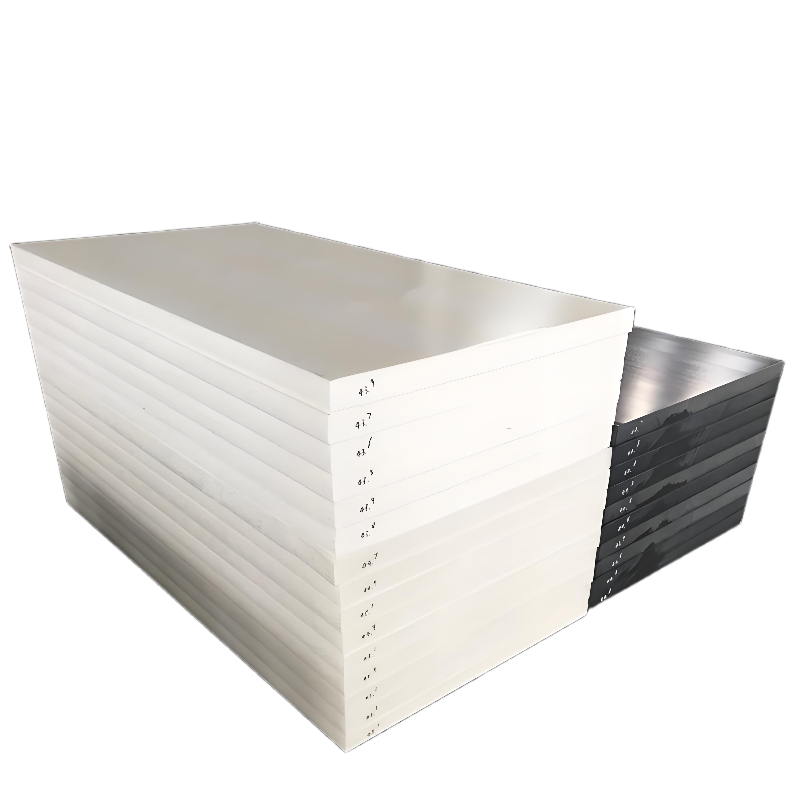

4.Attractive Surface Finish

They offer a smooth surface that can be painted, printed, or laminated, suitable for decorative and functional uses.

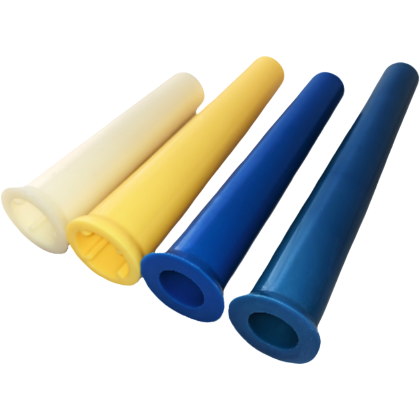

5.Chemical Resistance

ABS shows good resistance to many acids, alkalis, and oils, making it suitable for industrial environments.

6.Lightweight yet Durable

Despite being lightweight, ABS sheets have a long service life even under frequent use.

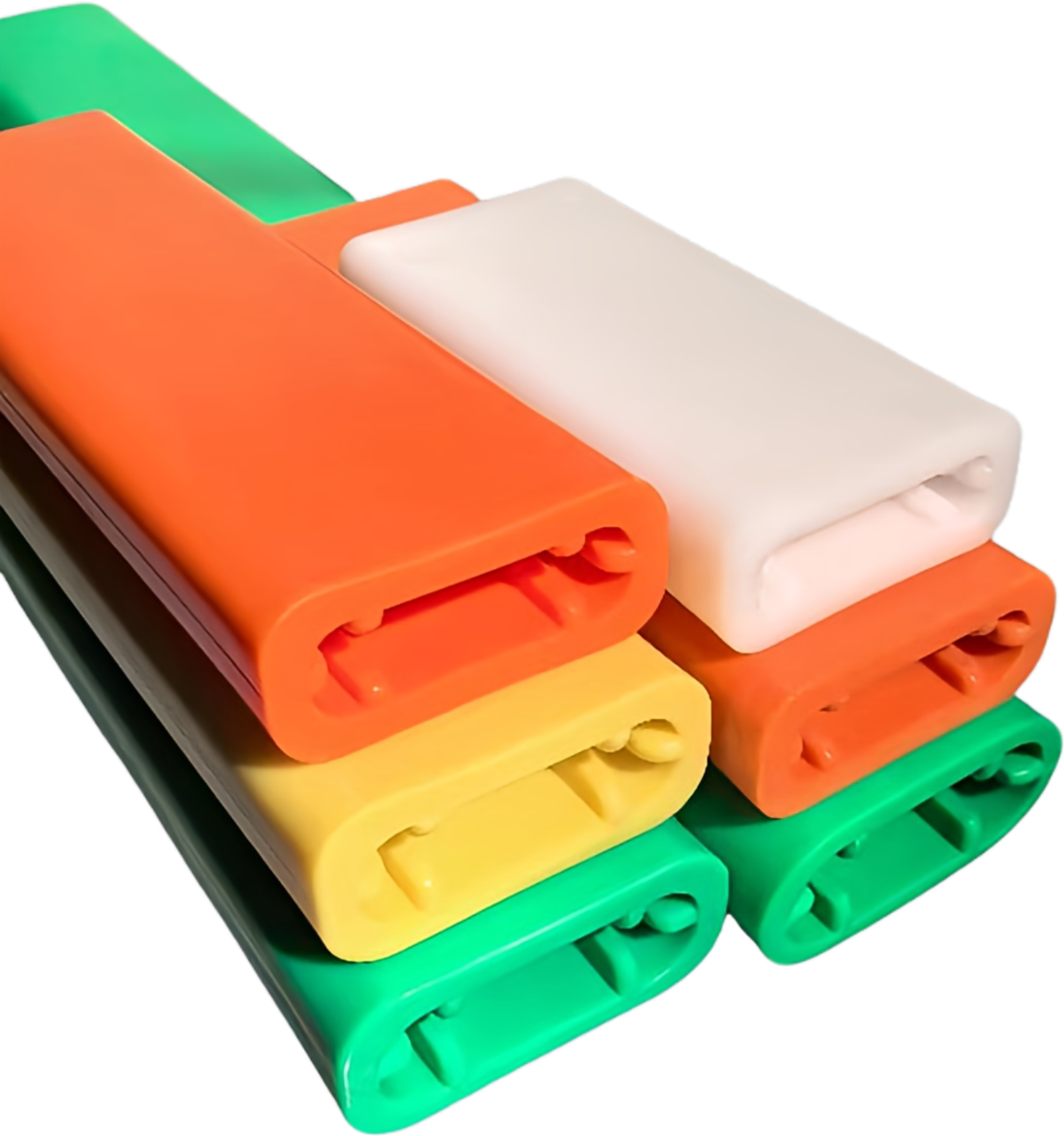

7.Good Electrical Insulation

They provide reliable insulation properties, useful in electrical and electronic applications.

8.Wide Temperature Range

ABS maintains performance across a broad temperature range (generally -20°C to +80°C depending on grade).