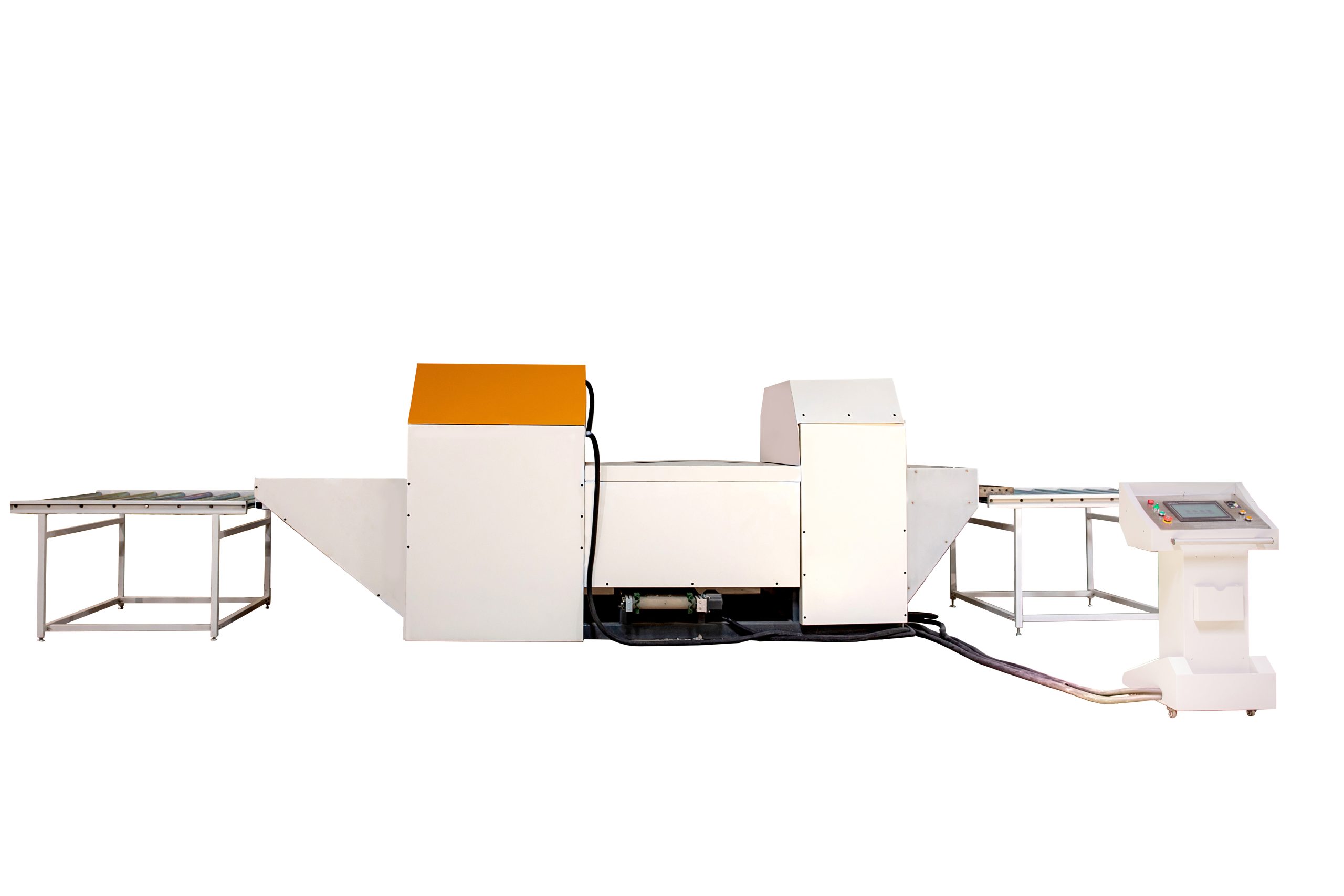

1.Good cleaning effect

The combination of high-frequency vibration and shot blasting machine can effectively remove all kinds of stubborn dirt on the surface of the aluminum template, and the surface of the aluminum template is clean after cleaning.

2.High cleaning efficiency

The aluminum template can be straightened during the cleaning process to meet the demand for rapid turnover of aluminum templates in building construction.

3.High degree of automation

The whole process from conveying, cleaning to sending out of aluminum template can be completed automatically, which reduces manual operation, lowers labor intensity and improves work efficiency.

4.Energy-saving and environmental protection

The filtered concrete slag is centrally stored, while the motor and other parts of the equipment adopt energy-saving design to reduce energy consumption.

5.Easy to operate

Control system interface is simple, intuitive parameter settings, staff can skillfully operate the equipment after simple training.