1. Hexagonal design is easy to use tools for quick tightening.

2. Adopting high-strength steel, corrosion-resistant and abrasion-resistant.

3. Mountain structure increases friction and effectively prevents the nut from loosening.

-

-

PRODUCTS

-

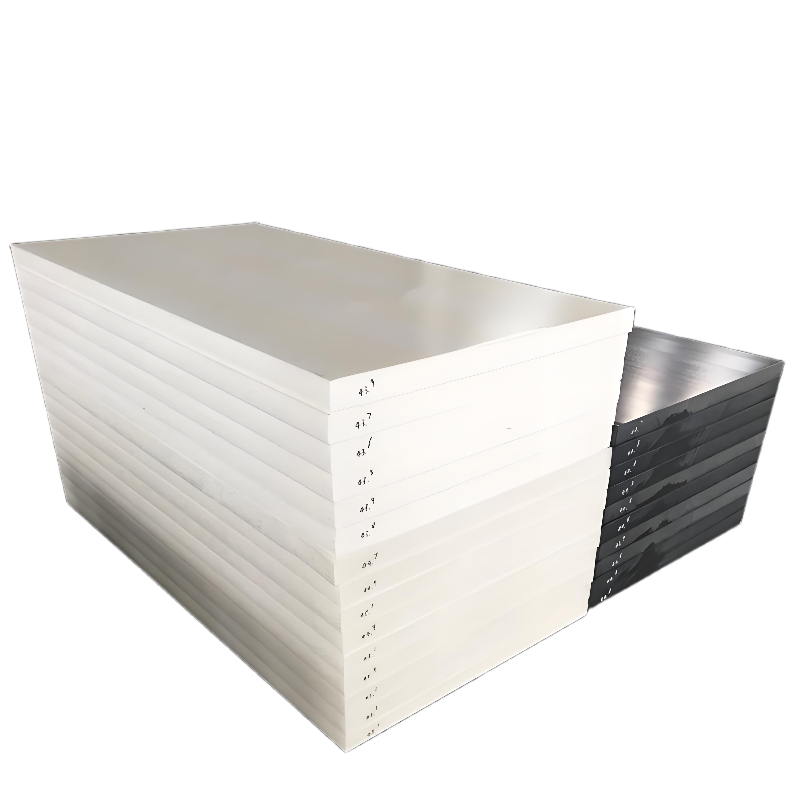

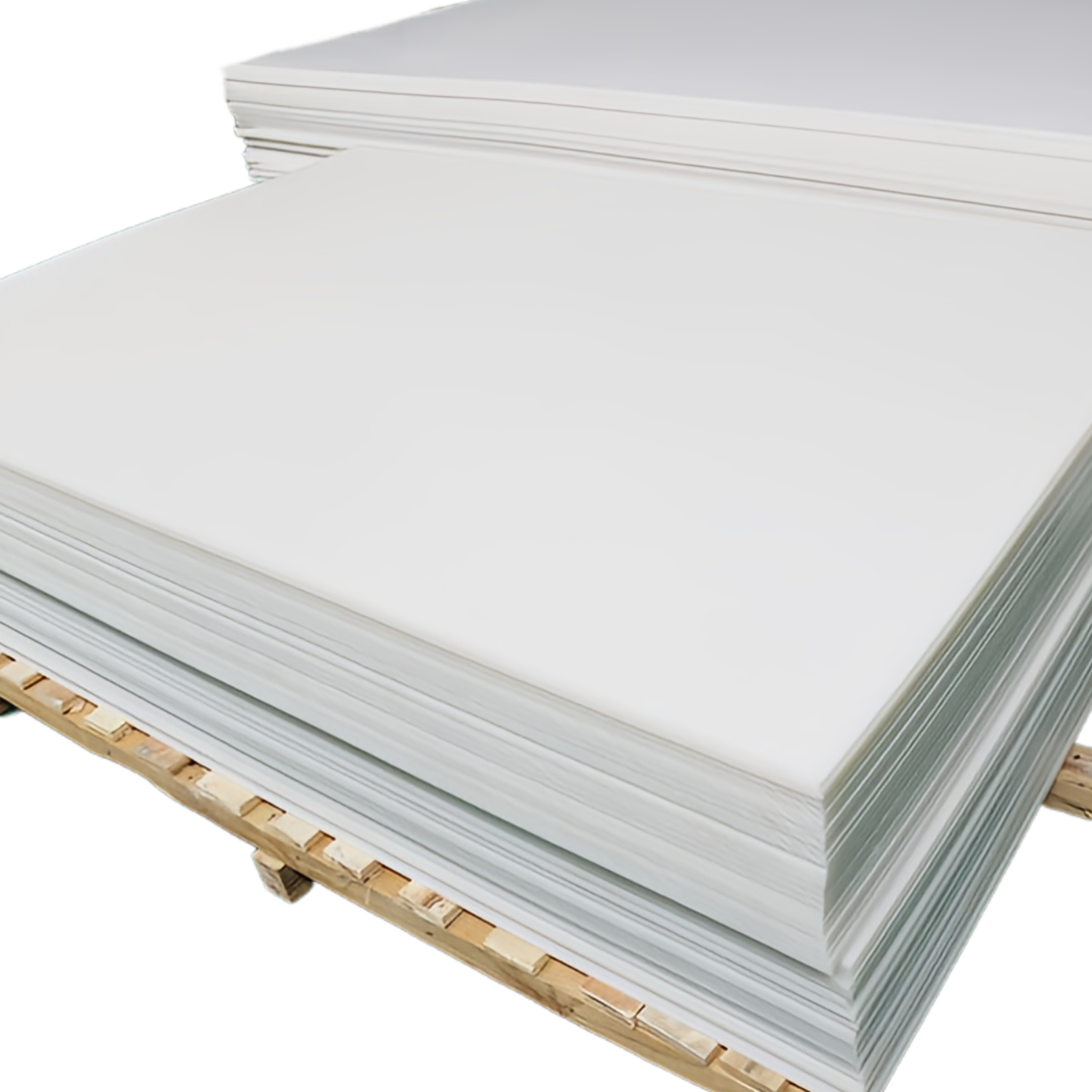

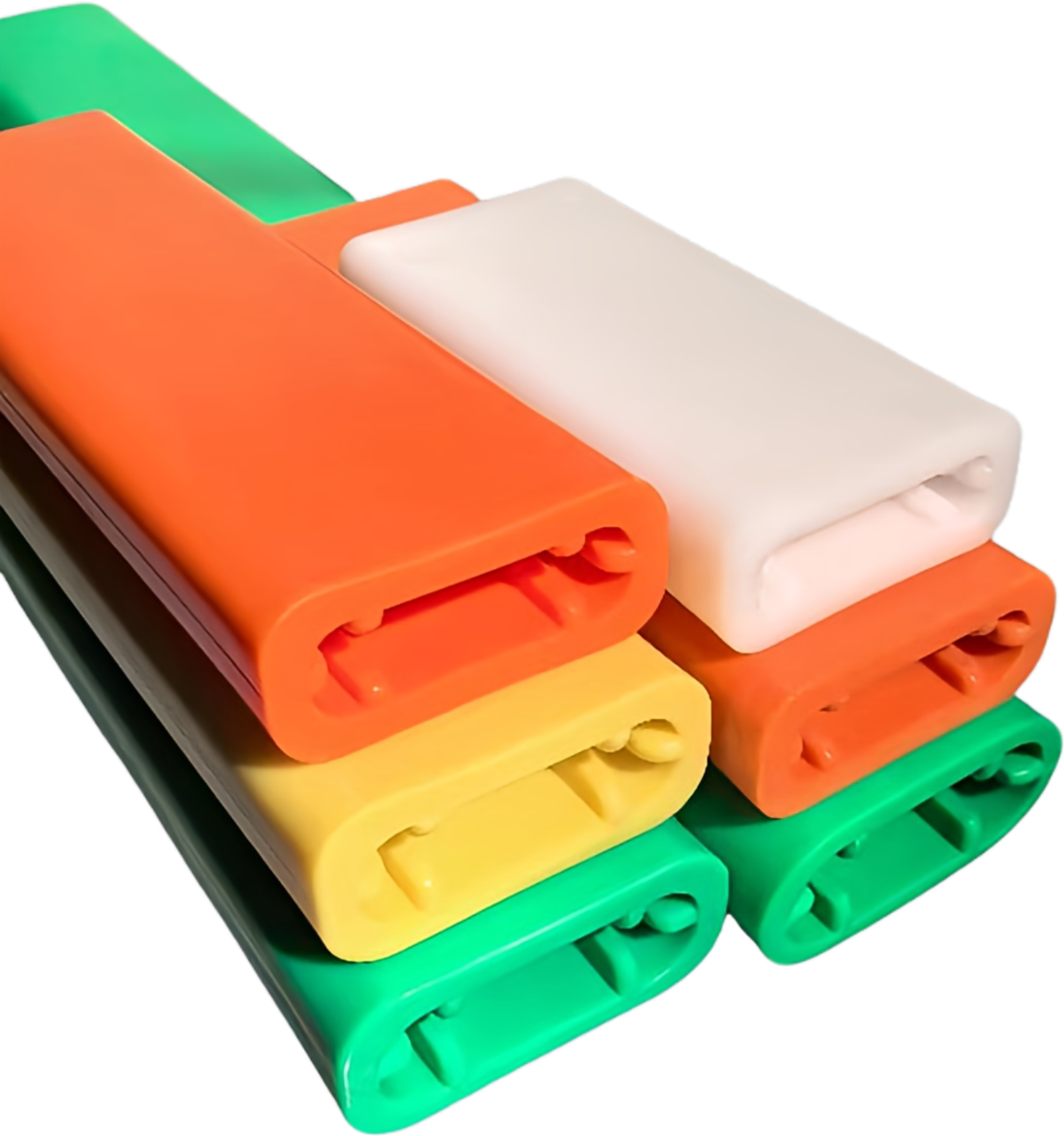

Plastics Sheet

-

Polypropylene Board (PP)

-

Polyethylene Board (PE)

-

Polycarbonate Board (PC)

-

Polystyrene Board (PS)

-

Polyvinylchloride Board (PVC)

-

Polyoxymethylene Board (POM)

-

Acrylonitrile-butdiene-styrene Board (ABS)

-

Acrylic Board(PMMA)

-

Polyether Ether Ketone Sheet(PEEK)

-

Polysulfone Sheet (PSU)

-

Polyurethane Sheet (PU)

-

Polyethylene Terephthalate Glycol-modified Plastic Sheet(PETG)

-

Polyethylene Terephthalate Sheet (PET)

-

Ultra-High Molecular Weight Polyethylene Sheets (UHMW)

-

Uhmwpe Sheet(UPE)

-

Polybutylene Terephthalate(PBT)

-

High density polyethylene(HDPE)

-

Polyetherimide Sheet(PEI )

-

Wood Plastic Composite Sheet(WPC)

-

-

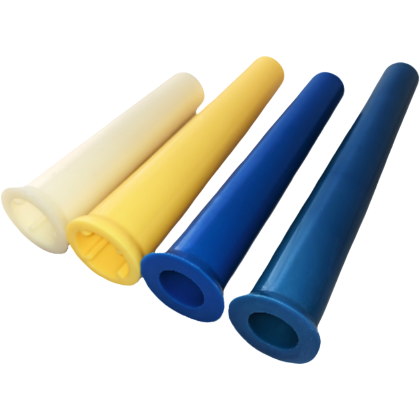

Plastic Rods

-

Construction Accessories

-

Aluminum Formwork

-

Refurbished Machine

-

-

SOLUTIONS

-

ABOUT US

-

PARTNERSHIP

-

BLOGS

-