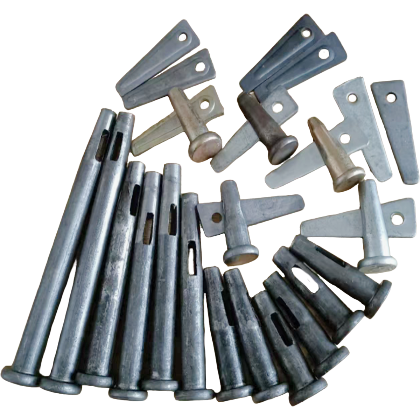

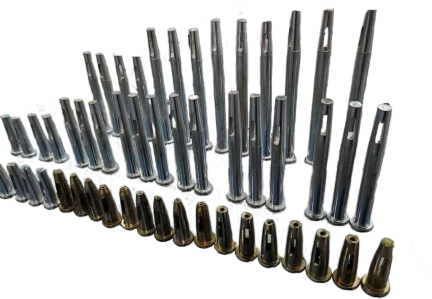

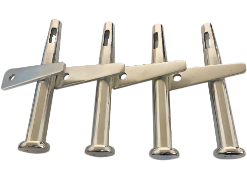

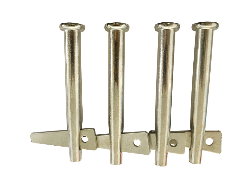

long pins

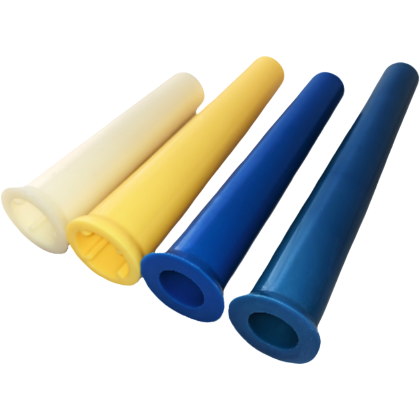

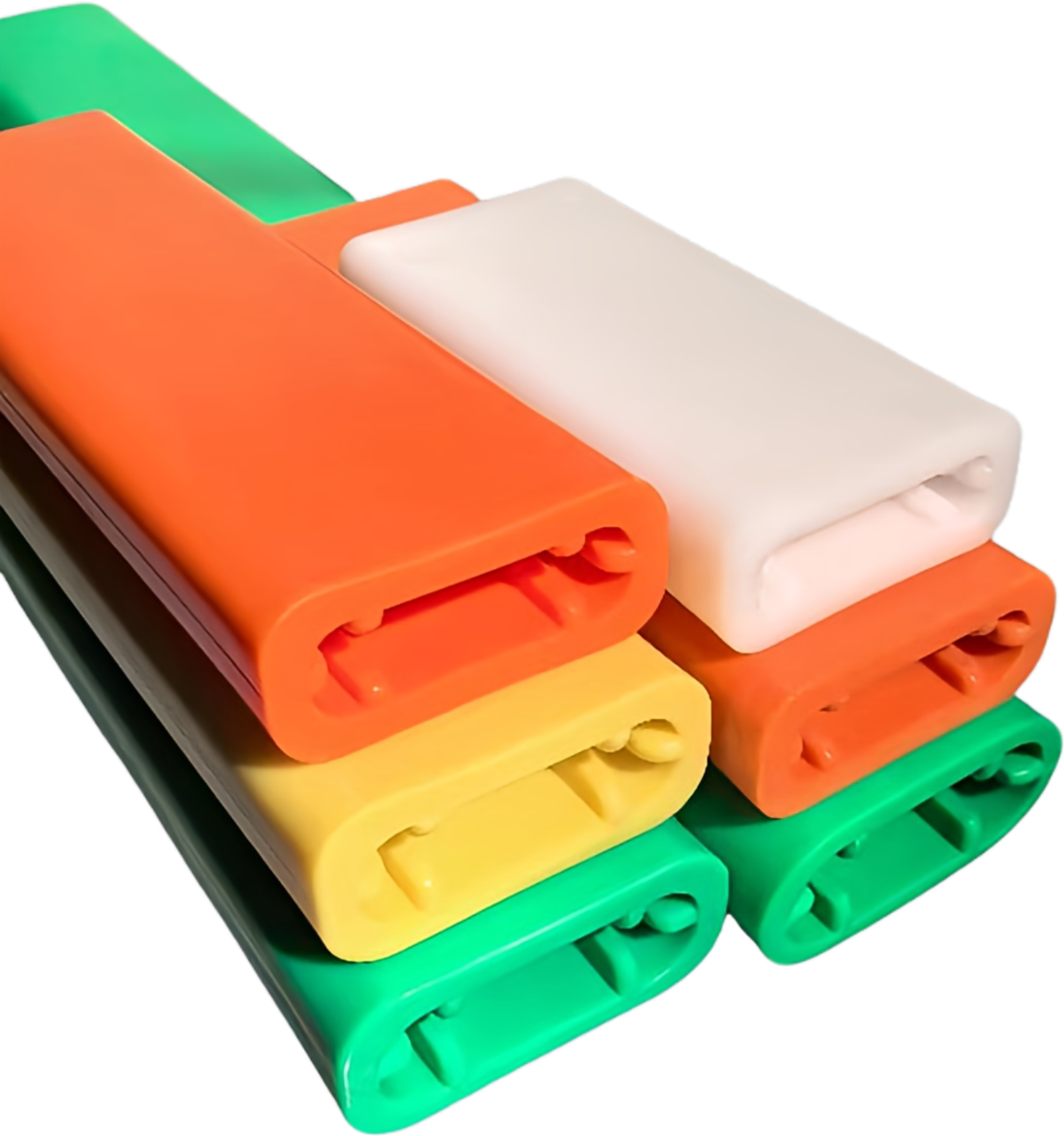

1. Strong durability, suitable for multiple disassembling and assembling, reducing cost.

2. Strong bearing capacity, which can ensure the safety and reliability of the formwork system.

3. Flexible installation, can be adjusted according to the construction needs of the use of position.

4. Solid connection, longer length, suitable for thicker formwork or scenes requiring greater connection strength.