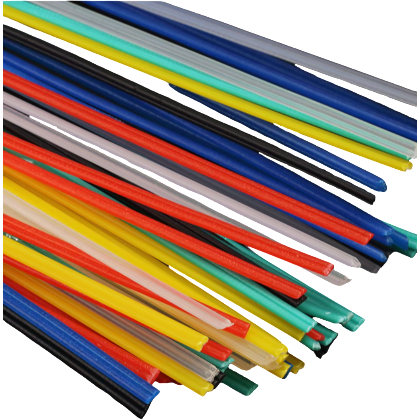

Plastic Welding Rods

Plastic welding rod is a tool used to weld plastic materials with various types and characteristics for different application scenarios.

Plastic welding rod is a tool used to weld plastic materials with various types and characteristics for different application scenarios.

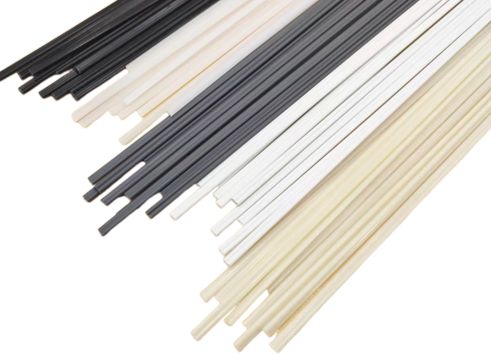

Color:

White, beige gray, black, translucent natural color.

Features:

High temperature resistance (over 100 ℃), corrosion resistance, lightweight and low density.

Application:

Automobile bumpers, door panels, washing machine barrel welding, electroplating equipment, PP wind pipe, turtle box, fishing boats, chemical containers (such as PP tanks, pipe fittings) and other systems and welding.

Color:

Black, white common, support customization needs.

Features:

Excellent acid and alkali resistance, good toughness, welding interface flat and firm.

Application:

Mostly used for general-purpose plastic products welding, such as automobile fuel tanks, air ducts, trash barrels, water pipes chemical barrels and so on.

Color:

Water grey, grey-based, support for customizing other colors.

Features:

Acid and alkali resistance, corrosion resistance, high mechanical strength.

Application:

Chemical anti-corrosion equipment (such as reaction tanks, pipes, etc.)

PVC sheet welding (such as sinks, door and window frames)

Color:

Beige-based.

Features:

Strong impact resistance, high surface finish, easy to process.

Application:

Automobile bumpers, plastic buckets and other ABS products repair.

Home appliance shell, electronic parts welding.

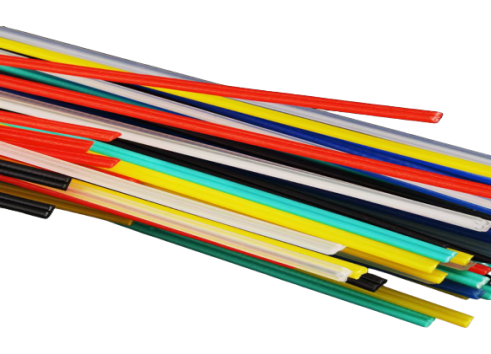

Specifications:

1.Single strand welding rod: suitable for fine construction welding.

2.Double strand welding rod: suitable for large area repair and reinforcement, commonly used in the chemical environment of the pipeline and plate welding.

3.Triple strand electrodes: for larger welding operations, such as splicing and reinforcement of plastic sheets.

4.Triangle welding rods: for applications requiring a specific shape of welding, such as the welding of triangular structures.

5.Circular welding rods: for welding operations that require circular interfaces.

Customization:

Support customization of color, diameter, and packaging specifications.

It’s different. Plastic welding rods are melted by heating and fused with the welded parts for connection; Metal welding rods use high-temperature electric arcs to locally melt and bond the welding rod and workpiece.

Plastic welding rods are suitable for use with a wide range of thermoplastics, including PP, PE, PVC, ABS, and others. The choice of welding rod depends on the specific plastic material being welded.

When choosing the right plastic welding rod, consider the type of plastic being welded, the thickness of the material, and the welding method (e.g., hot air welding or extrusion welding). Ensure that the welding rod is compatible with the base material for best results.

Plastic welding rods should be stored in a cool, dry place away from direct sunlight and moisture. Avoid high temperature and physical damage to maintain its quality and performance.

The color is usually determined by the addition of colorants and is not related to the basic performance. As long as the material and specifications are the same, the performance is basically the same.

Unused and well preserved reusable items; Welded or deteriorated due to heat, the performance has changed, affecting the welding quality.

Low cost, simple process, no need for complex equipment, good compatibility with plastic welding parts.

Guangdong Chuangiangshu New Materials Co.,Ltd

Guangdong Chuangiangshu New Materials Co.,Ltd

No.9, Lane 1, Heng Jiang Nan San Yuan, Shatou Street, Panyu District, Guangzhou, China

Contact Number: +86 189 2759 8228

Email: edison@nmtplastics.com

WhatsApp: +86 189 2759 8228