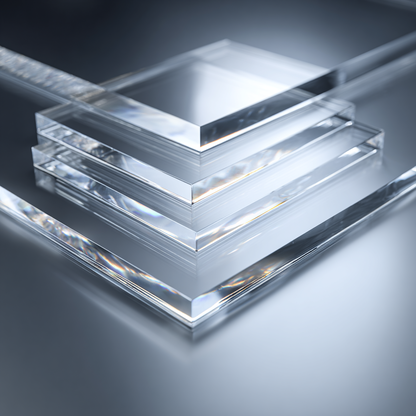

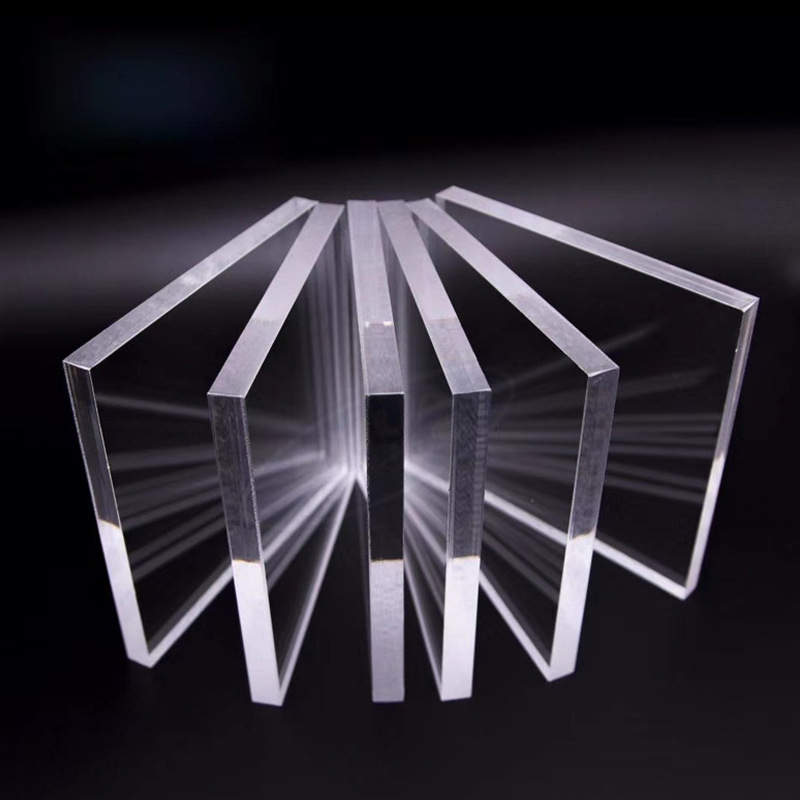

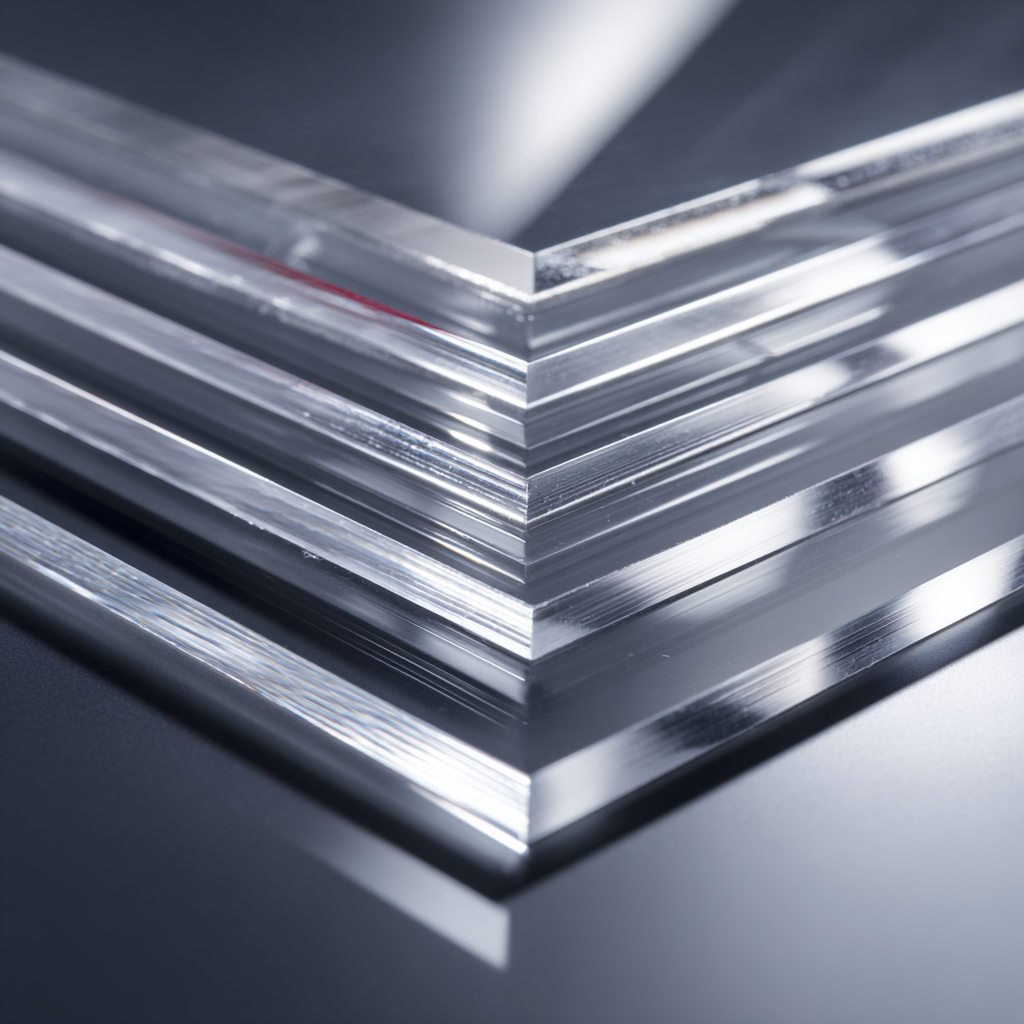

1.Optical Excellence: Over 95% light transmittance (superior to glass), with long-term UV resistance and no yellowing.

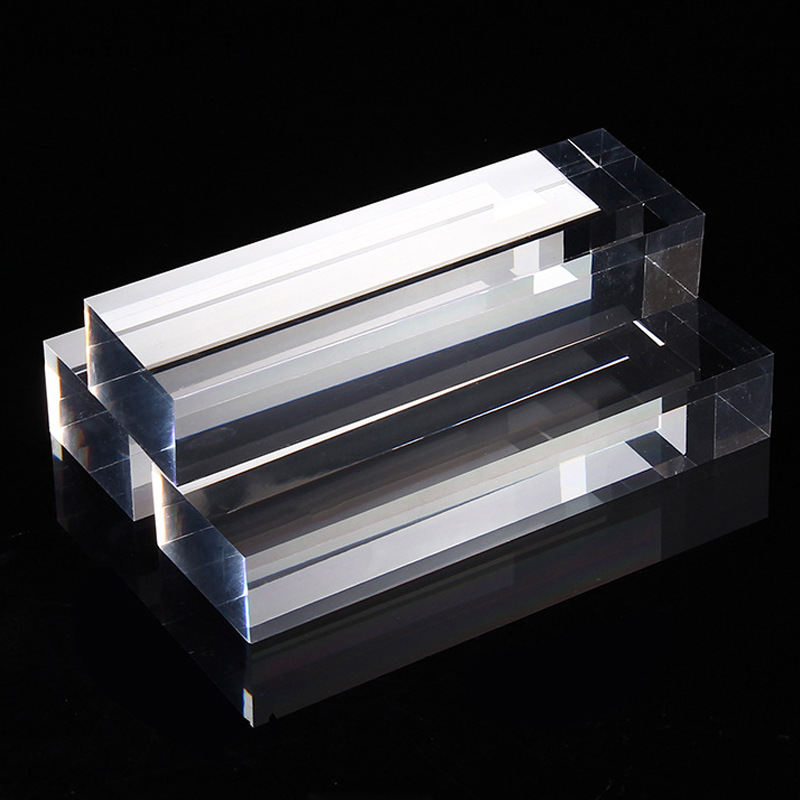

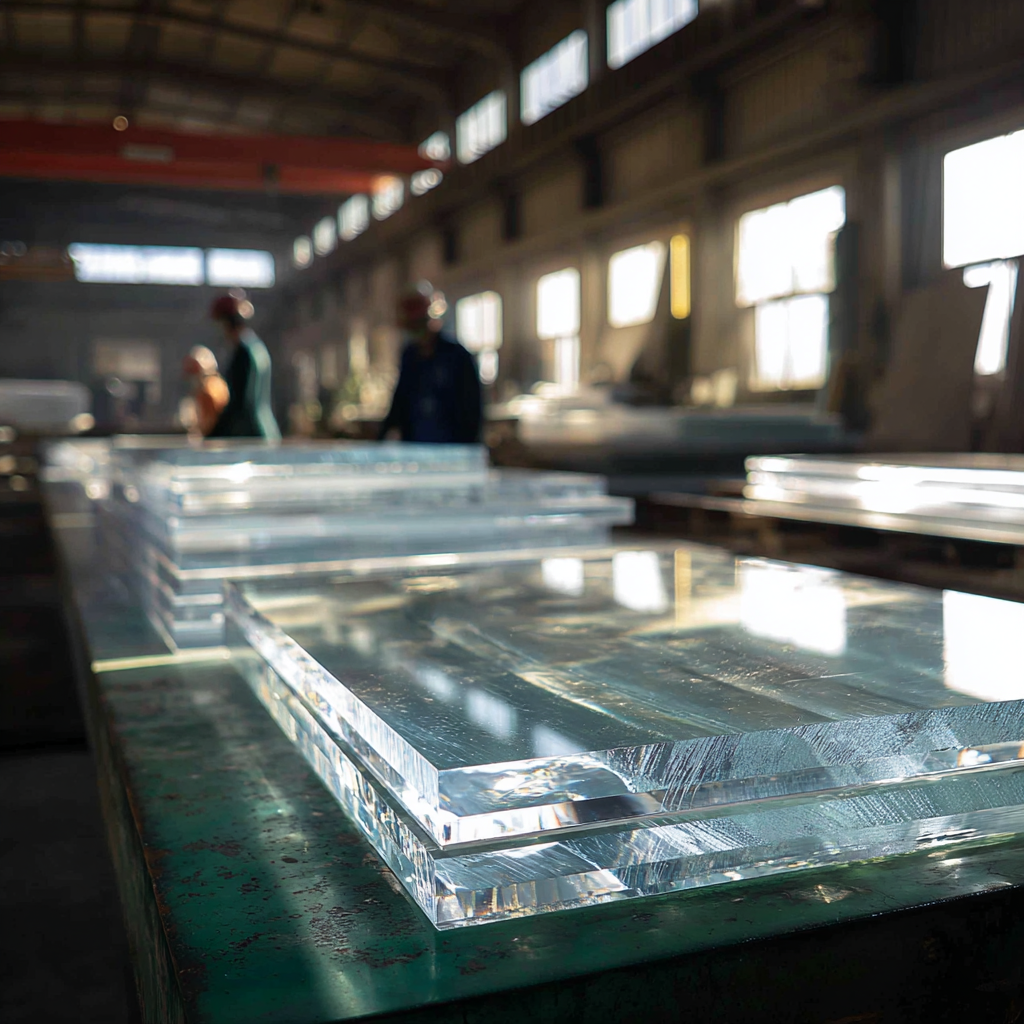

2.High Mechanical Strength: 10–20 times more impact-resistant than glass, with a density of only 1.2 g/cm³ (half that of glass).

3.Weather & Chemical Resistance: Stable in temperatures ranging from -40°C to 90°C, low water absorption (<0.3%), but soluble in acetone and chlorinated solvents.

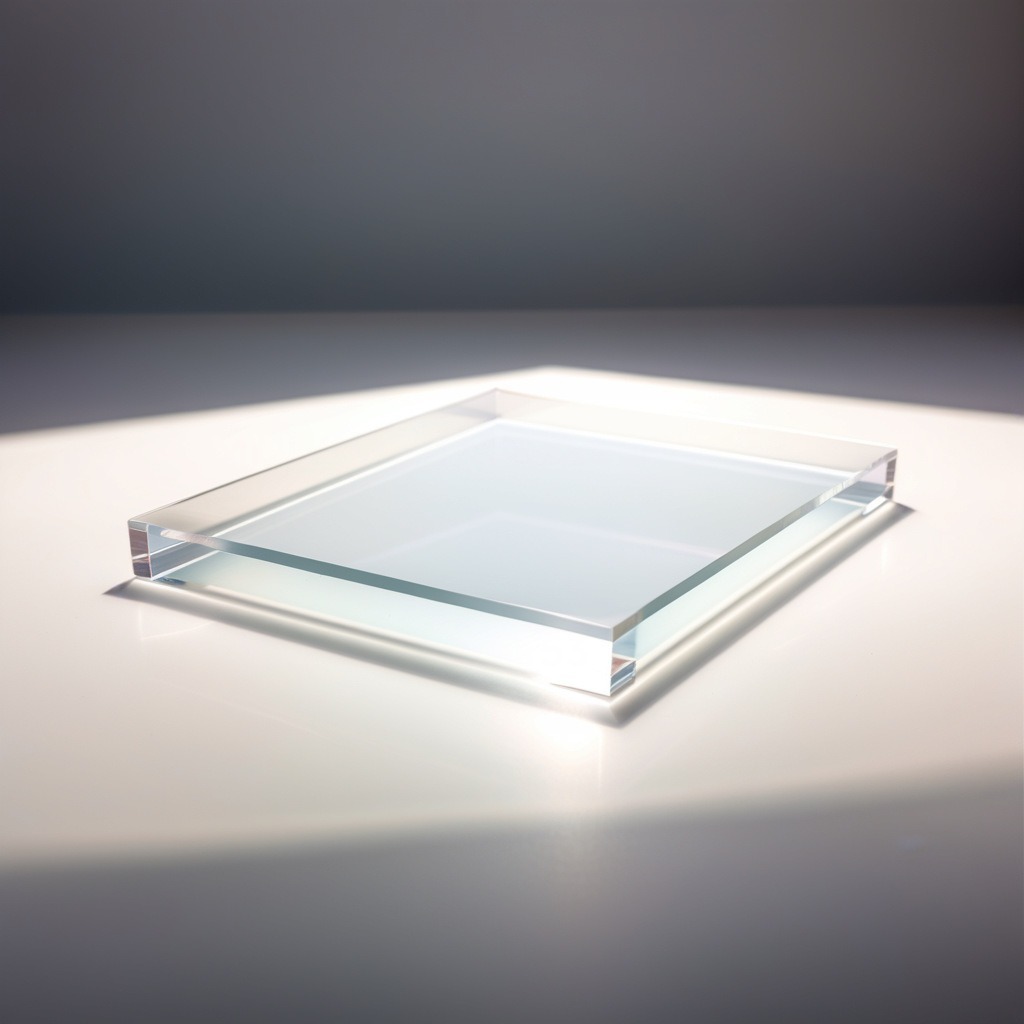

4.Superior Surface Properties: Scratch-resistant (often requires coating) and maintains high gloss for years.

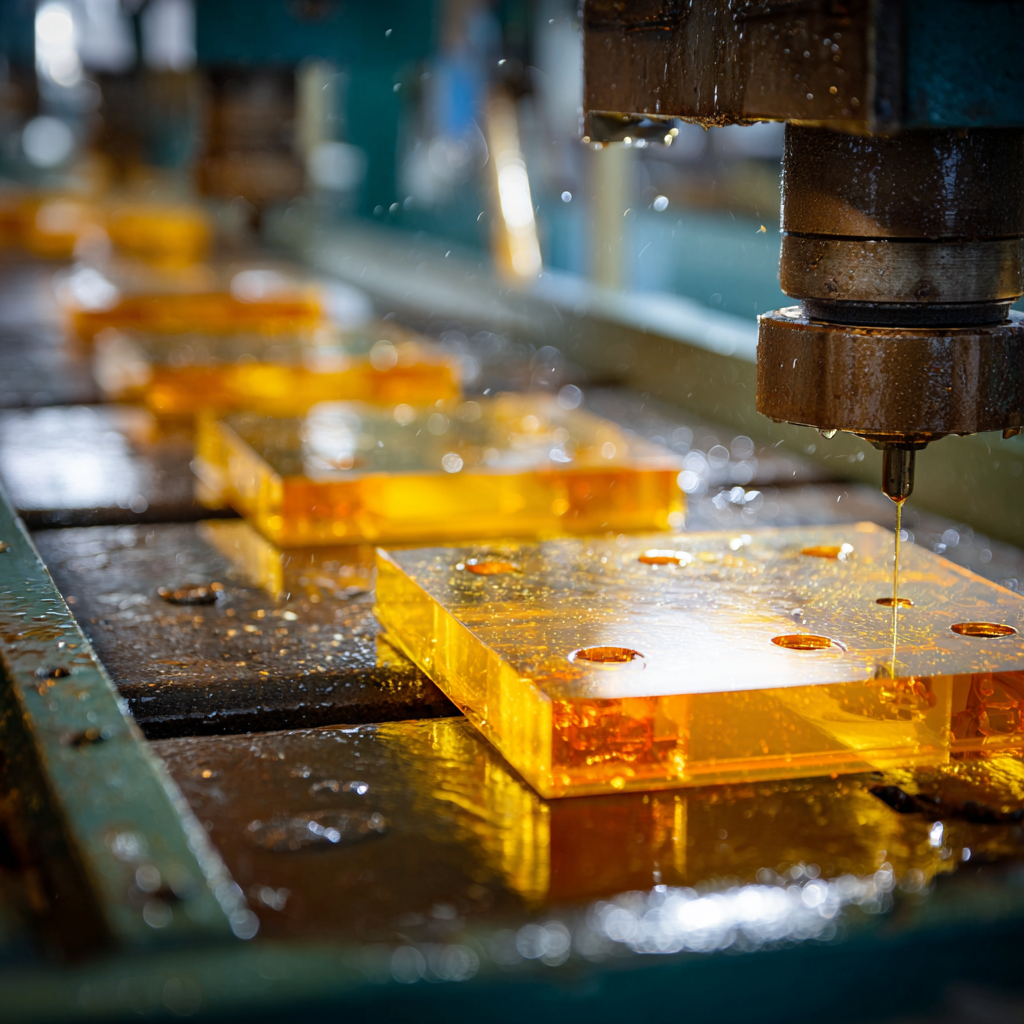

5.Easy Fabrication: Can be cut/drilled with woodworking tools, thermoformed at 150–160°C, and bonded using solvents or acrylic adhesives.

6.Safety & Eco-Friendliness: Flame-retardant (UL94 HB/V-2 rated), with minimal smoke/toxins when burned.

7.Excellent Electrical Insulation: Outstanding dielectric properties, ideal for electronic enclosures.