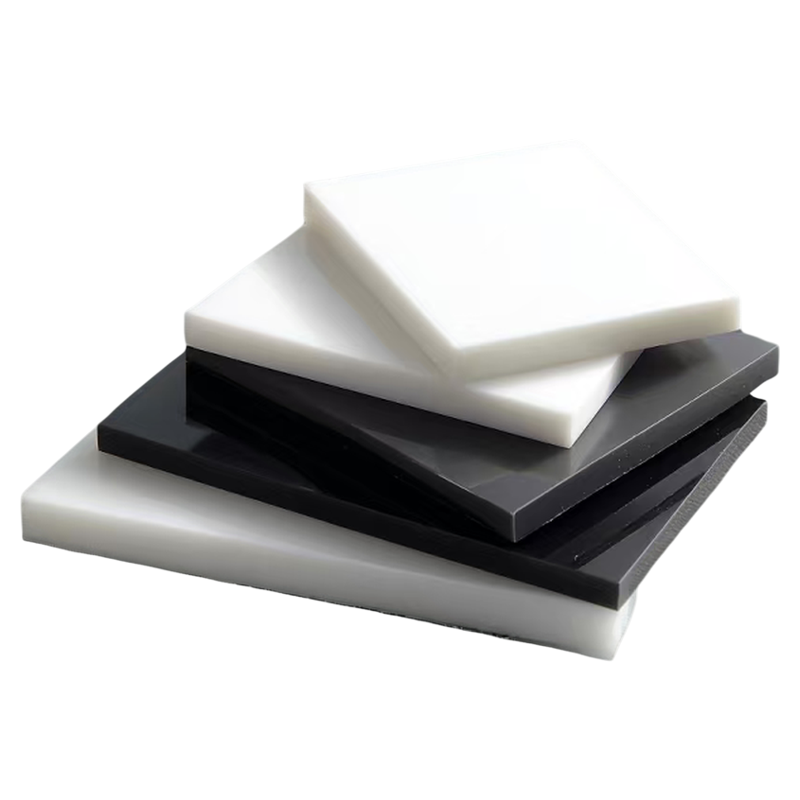

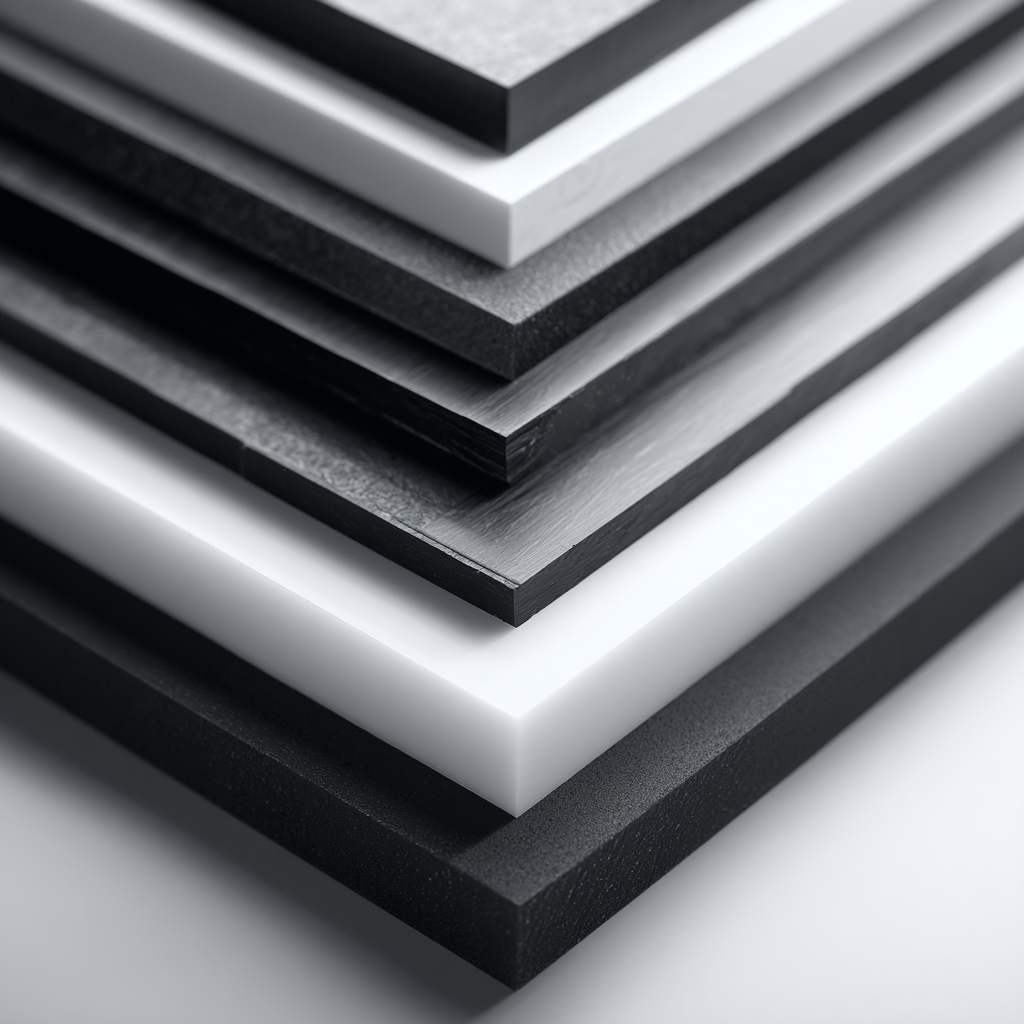

Polybutylene Terephthalate (PBT) Sheet

1.Excellent Chemical Resistance – Can withstand acids, alkalis, and many organic solvents, making it suitable for chemical processing and industrial applications.

2.High Impact Strength – Lightweight yet tough, offering strong resistance to impact and mechanical stress.

3.Lightweight with High Durability – Lower density than many other plastics ensures easy handling and reduced transportation costs without compromising strength.

4.Good Heat Resistance – Maintains mechanical properties at elevated temperatures, suitable for hot water or steam exposure.

5.Low Moisture Absorption – Ensures dimensional stability even in humid or wet environments.

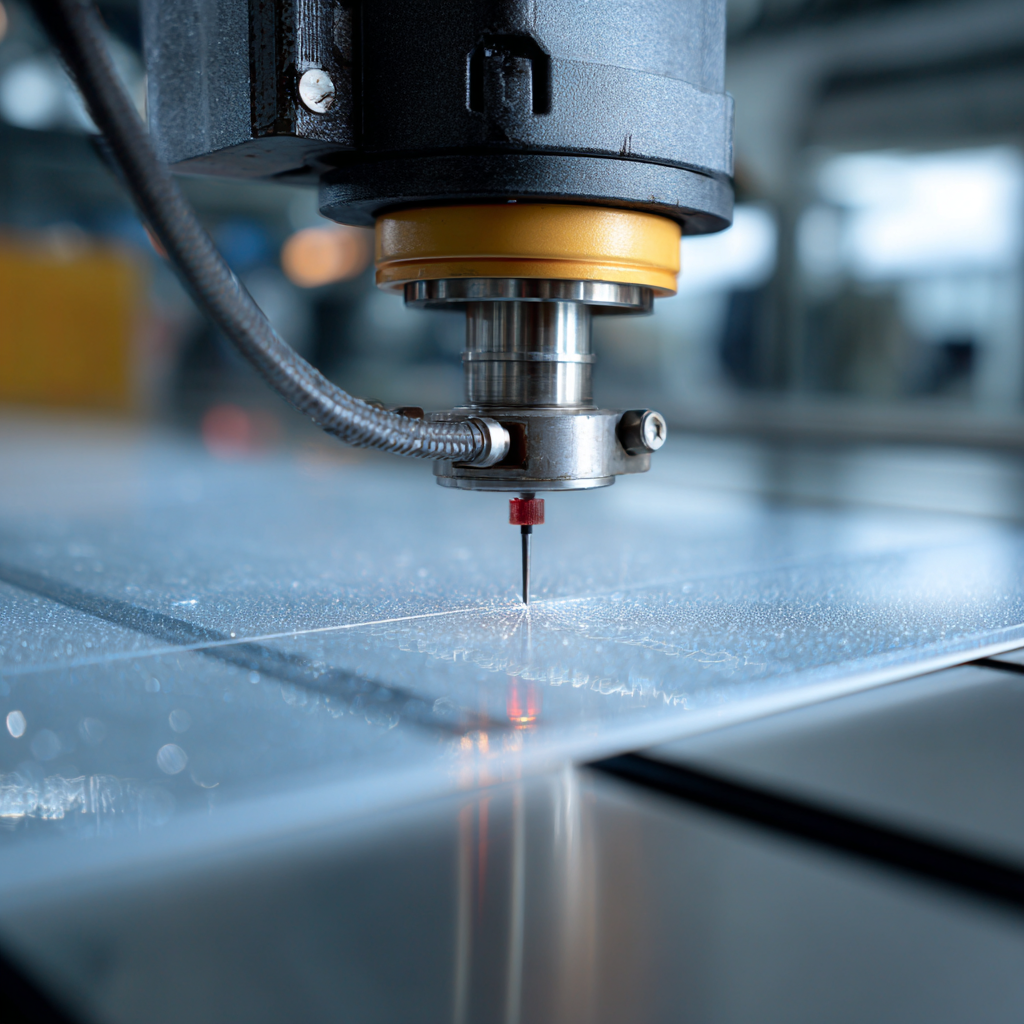

6.Excellent Machinability and Weldability – Easy to fabricate, cut, and weld into custom shapes, gears, or components.

7.Non-Toxic & Food-Safe – Suitable for food-contact applications, providing hygienic performance.

8.Cost-Effective – Combines durability, chemical resistance, and performance at a competitive price compared with other engineering plastics.