1.High Impact Strength – Extremely tough and virtually unbreakable, much stronger than acrylic or glass.

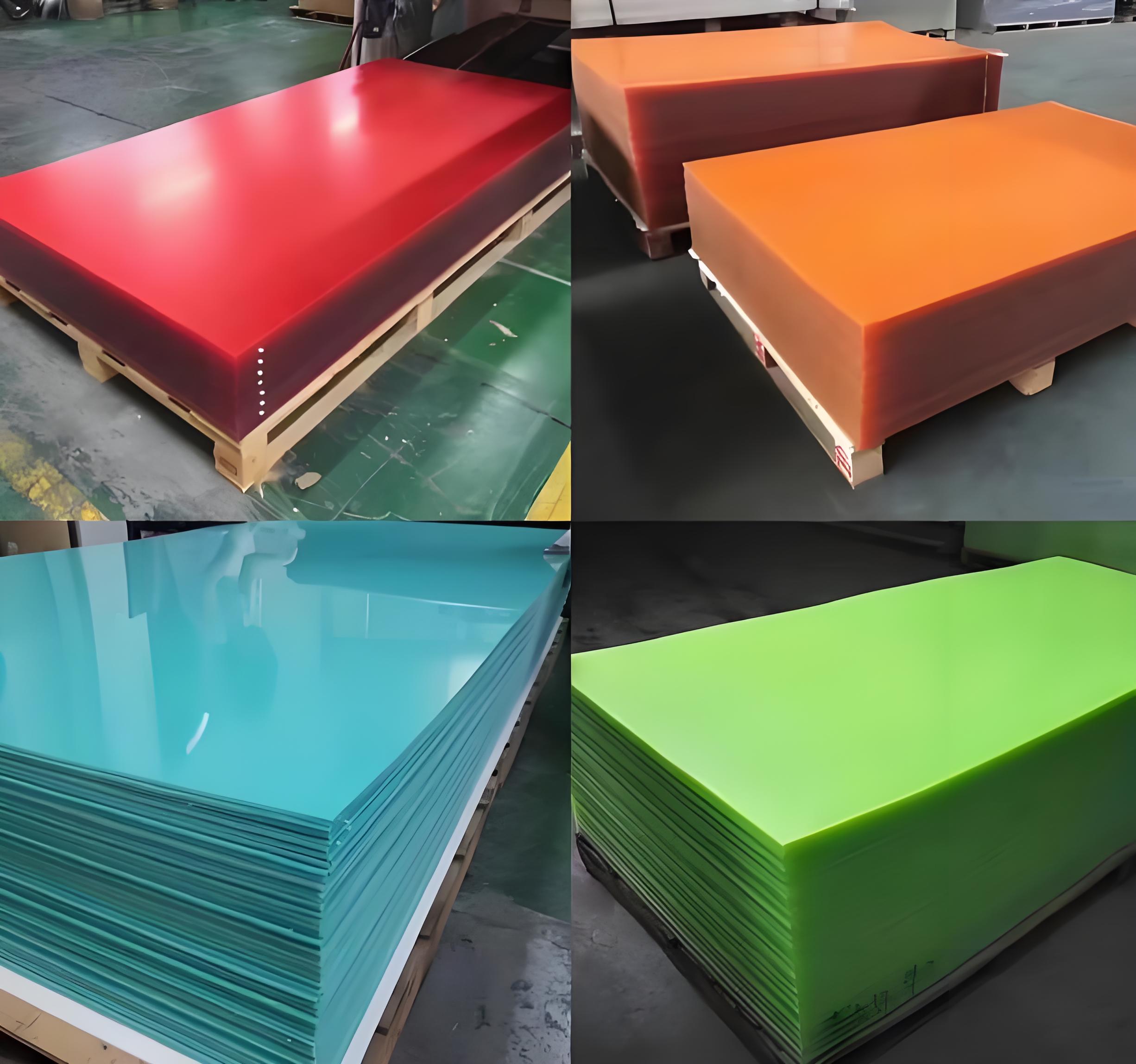

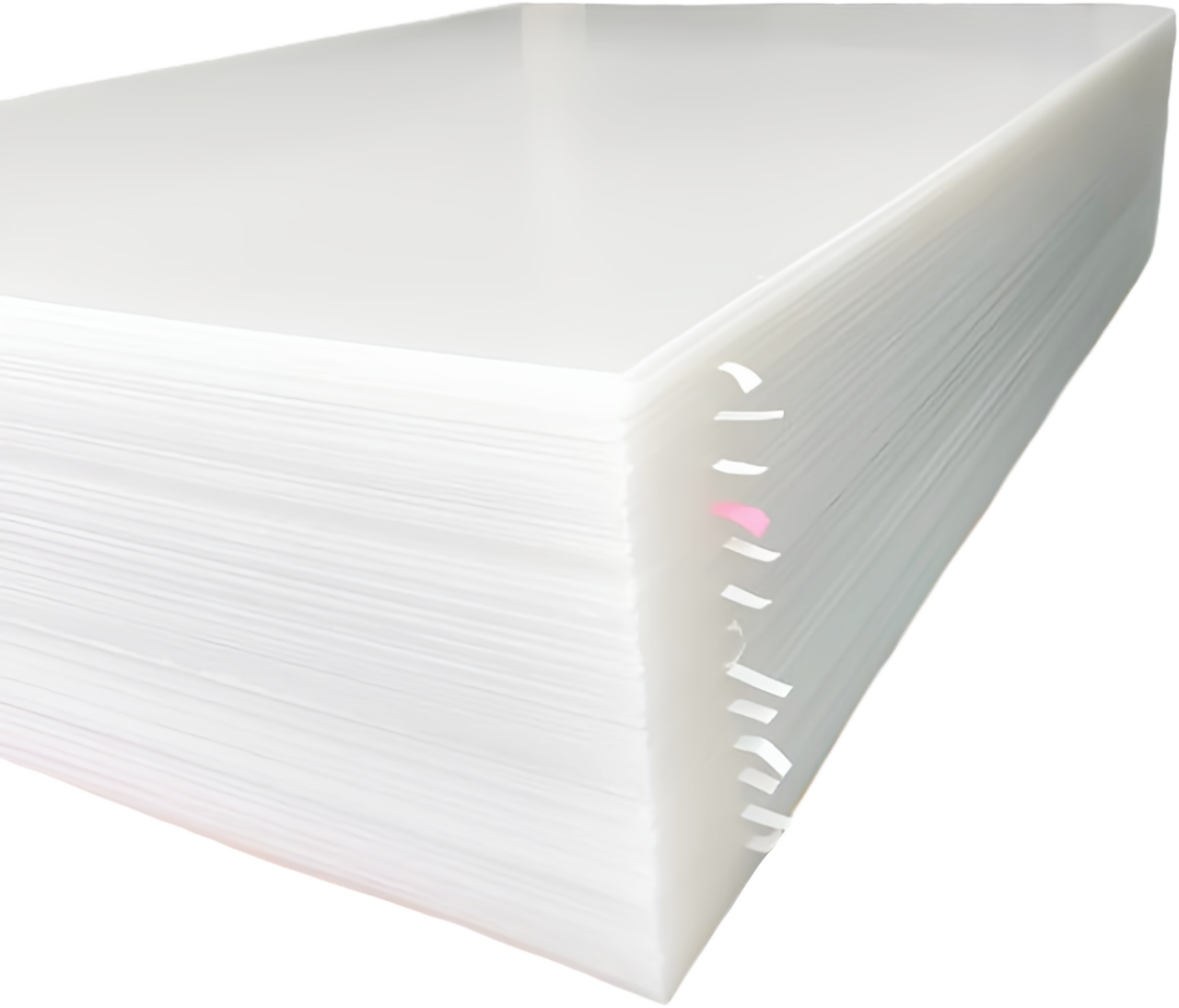

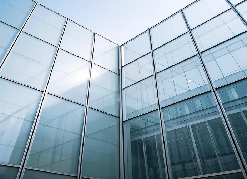

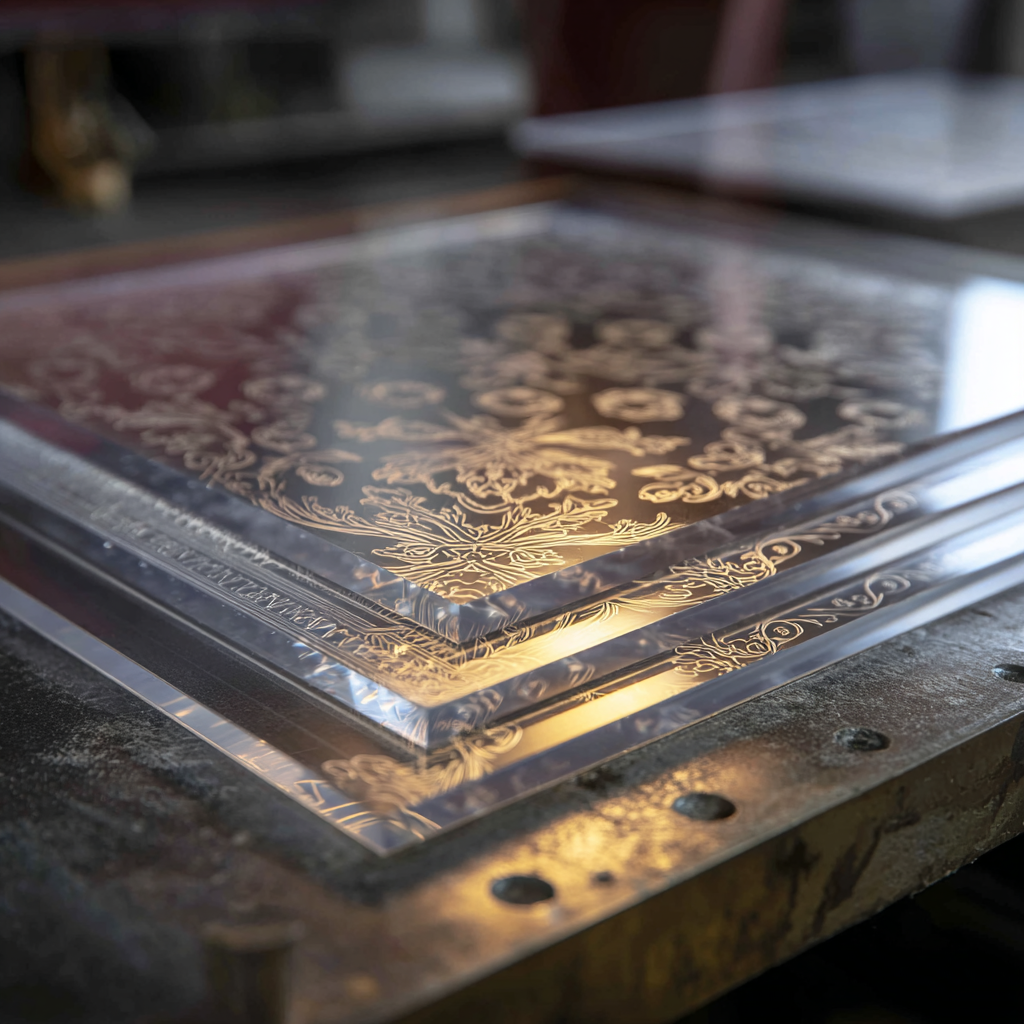

2.Excellent Optical Clarity – Transparent sheets with high light transmission (up to 90%), ideal for windows, shields, and displays.

3.Heat Resistance – Can withstand temperatures up to 135 °C continuously and short-term exposure up to 150 °C.

4.Lightweight – Strong yet lighter than glass, easy to handle and install.

5.Good Dimensional Stability – Maintains shape and mechanical properties across temperature changes.

6.UV Resistance (Optional) – UV-protected grades prevent yellowing and degradation under sunlight for outdoor use.

7.Flame Retardant Options – Available with self-extinguishing grades for safety-critical applications.

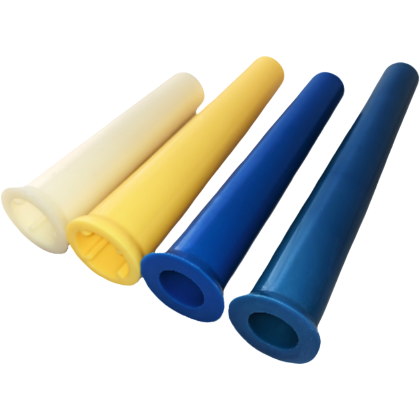

8.Electrical Insulation – Naturally non-conductive, suitable for electronic and electrical applications.

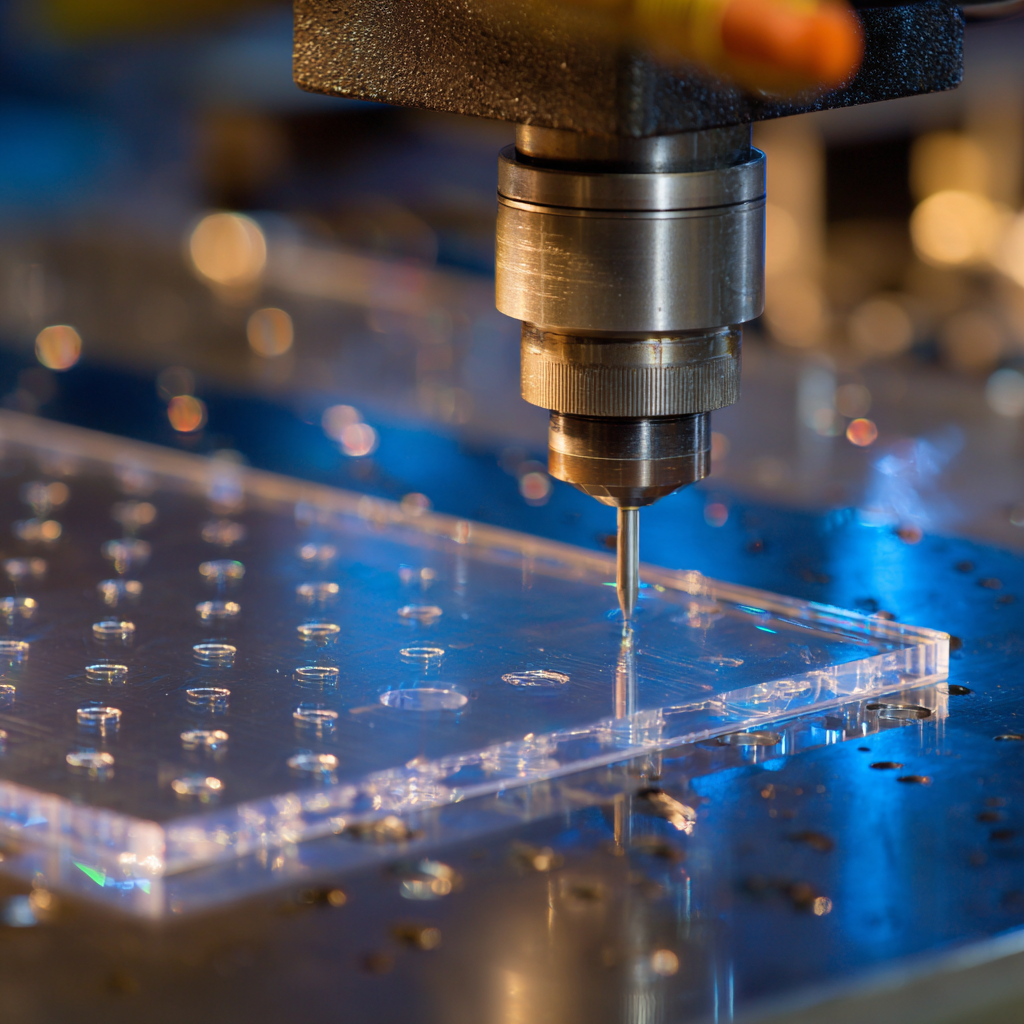

9.Easy Fabrication – Can be thermoformed, machined, drilled, cut, and polished.

10.Scratch & Abrasion Resistance (Optional) – Hard-coated grades provide improved surface durability.