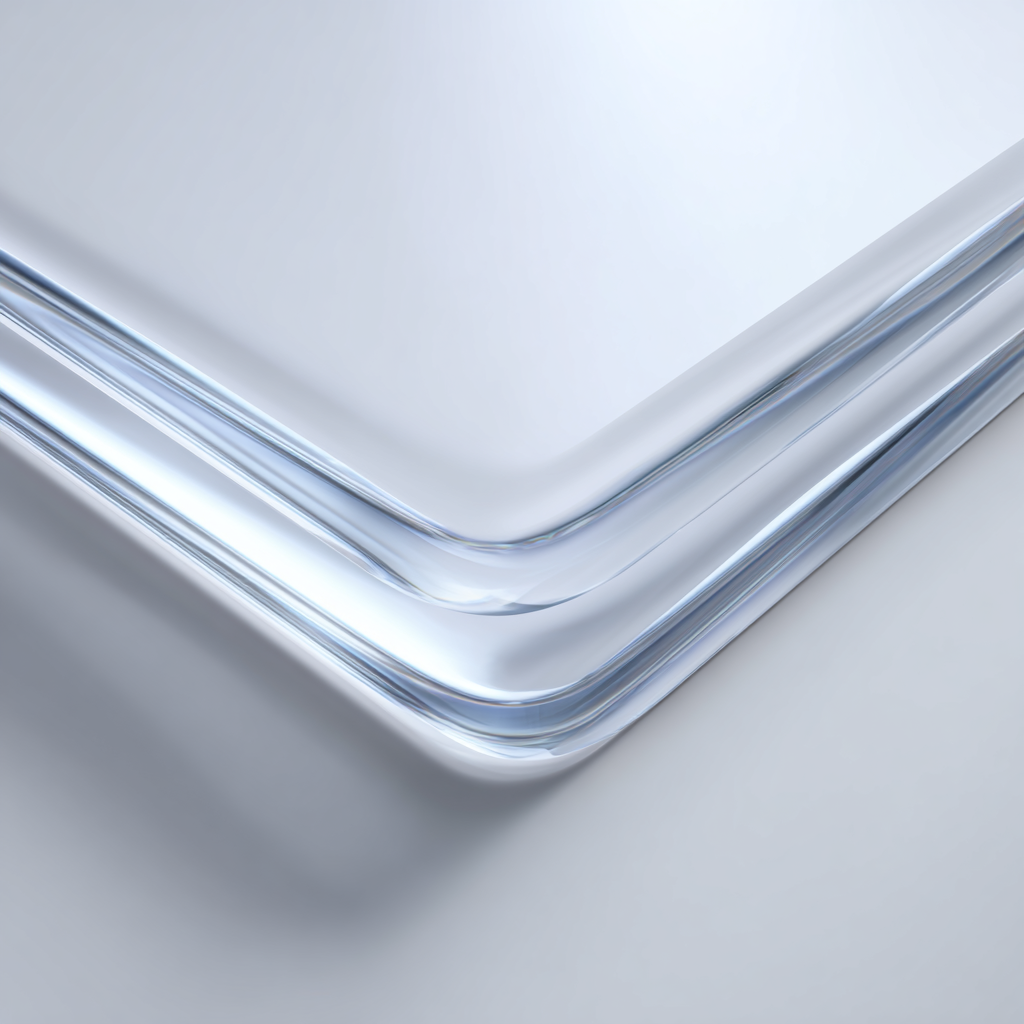

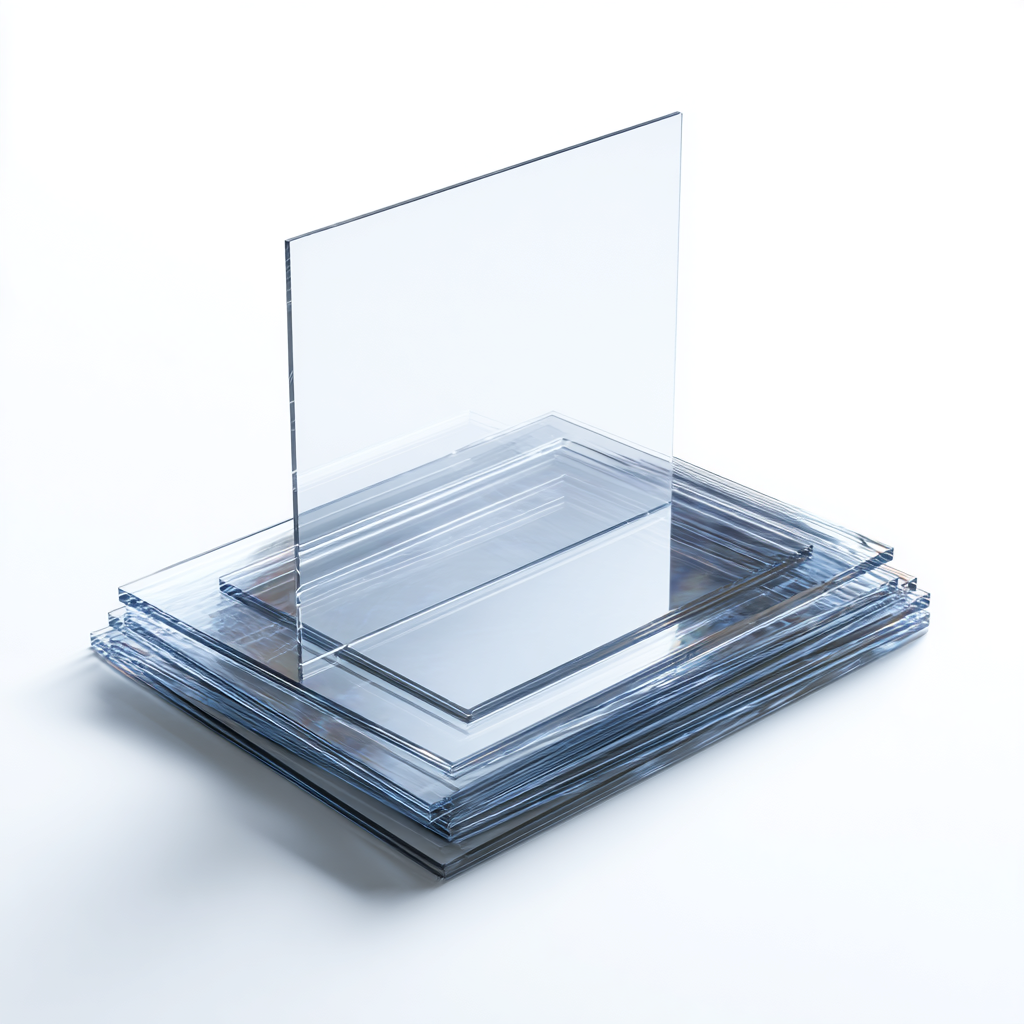

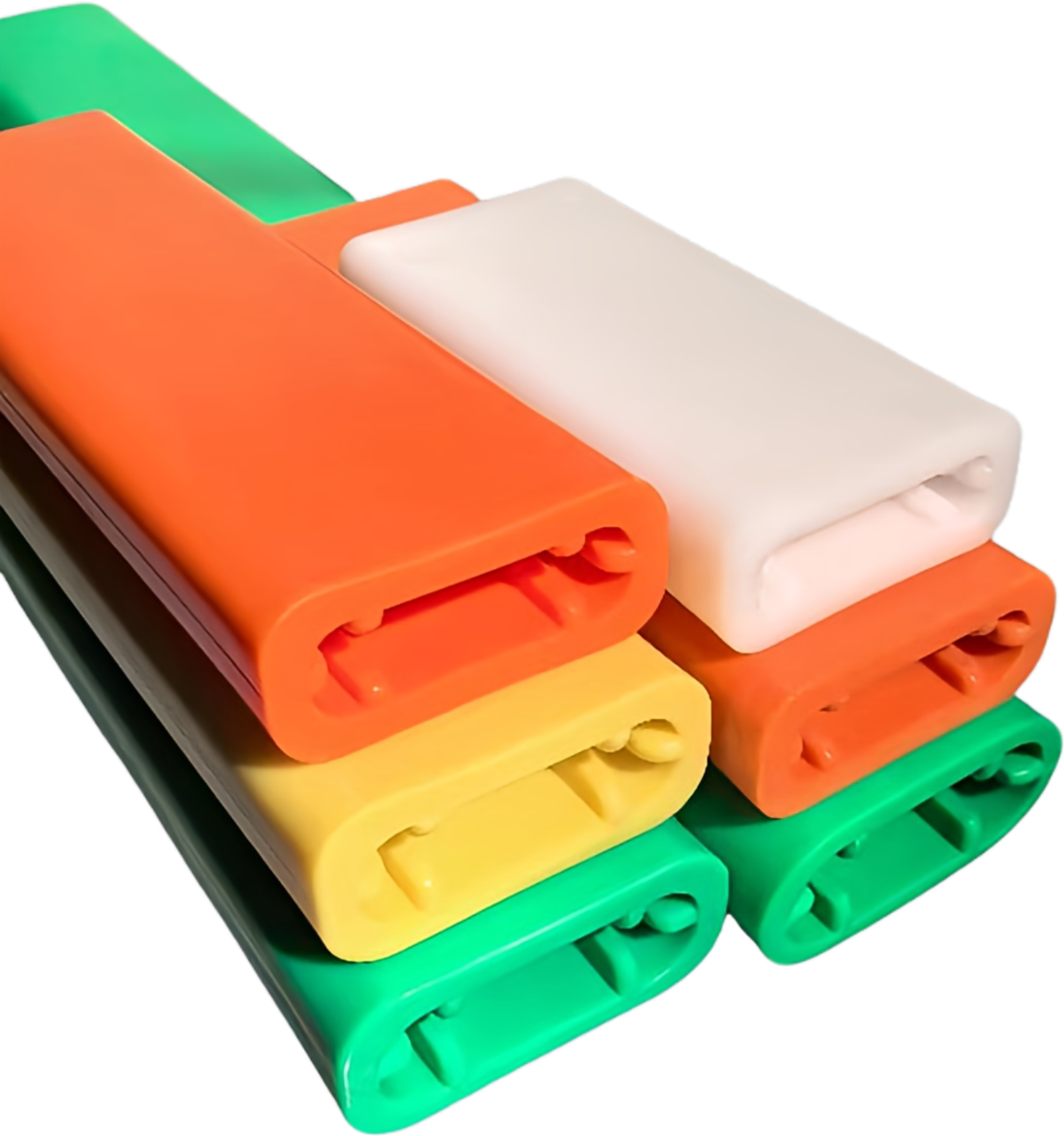

Polyethylene Terephthalate Glycol-modified (PETG) Plastic Sheet

1.Excellent Chemical Resistance – PETG sheets can resist a wide range of acids, alkalis, and mild organic solvents, making them suitable for applications in chemical processing, laboratory equipment, and protective coverings.

2.High Impact Strength – PETG boards are tough and offer superior impact resistance compared with standard acrylic sheets, reducing the risk of cracking or breaking.

3.Lightweight with High Durability – With a low density and strong mechanical properties, PETG sheets are easy to handle, transport, and install without compromising performance.

4.Good Heat Resistance – PETG maintains dimensional stability and mechanical properties at temperatures up to around 70–80 °C, suitable for most indoor and light outdoor applications.

5.Low Moisture Absorption – PETG sheets absorb minimal moisture, ensuring consistent shape and performance in humid or wet environments.

6.Excellent Fabrication and Formability – Easy to thermoform, cut, drill, and laser engrave, PETG is ideal for custom shapes, signage, and protective barriers.

7.Non-Toxic & Food-Safe – PETG is safe for many food-contact applications and medical devices, offering hygienic and FDA-compliant performance.

8.Cost-Effective Solution – PETG provides a balance of transparency, toughness, and chemical resistance at a competitive price compared to other transparent plastics.