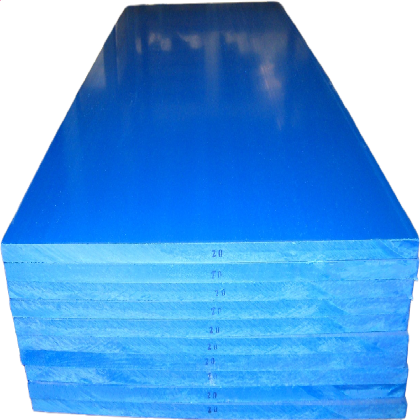

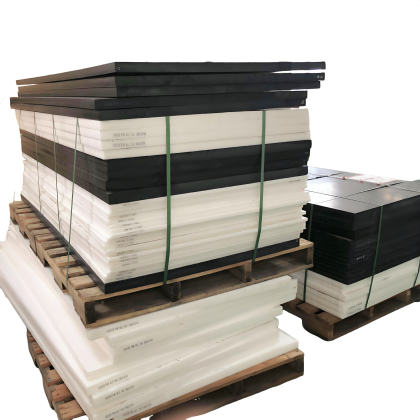

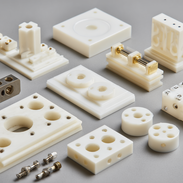

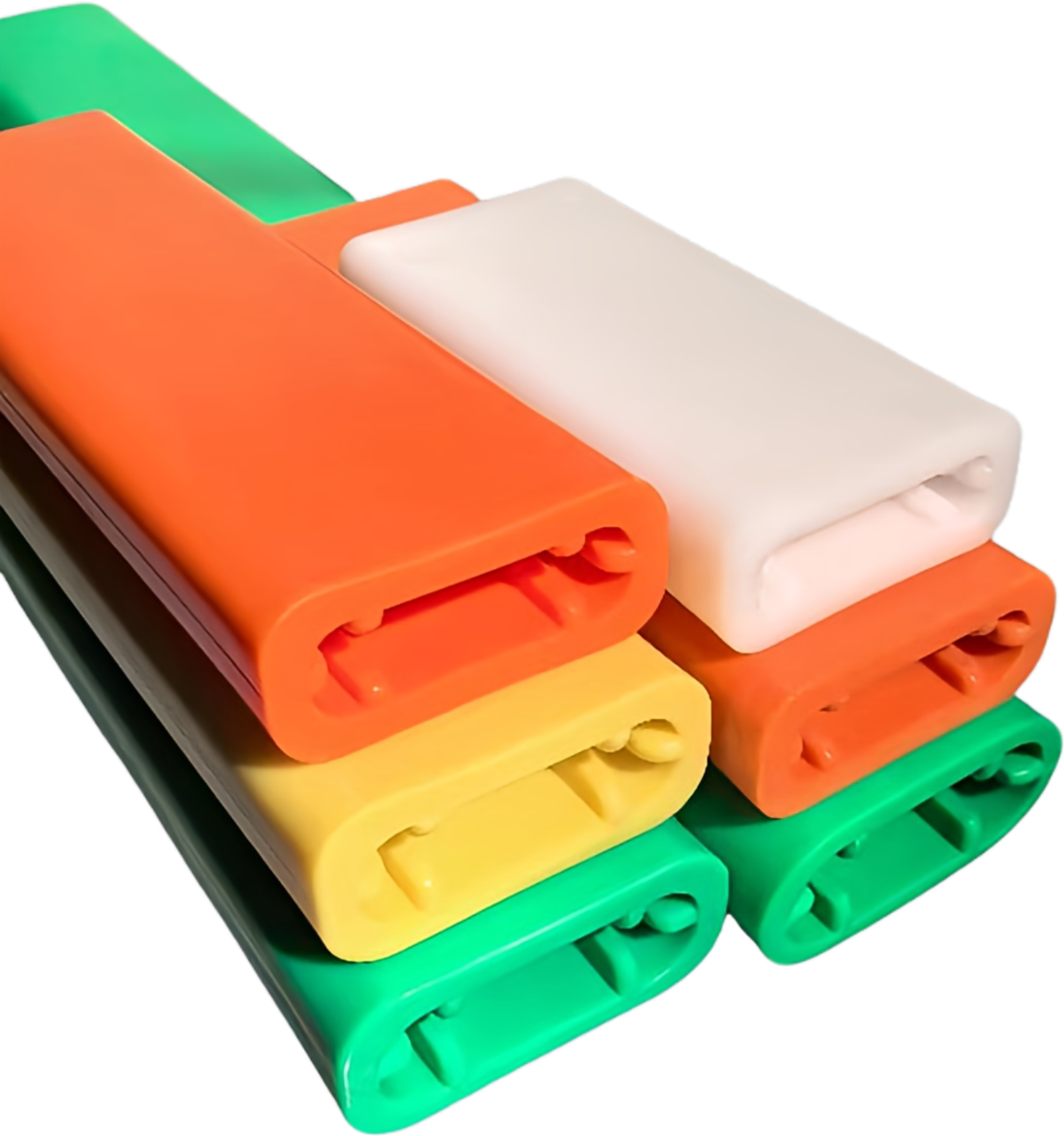

1.High Mechanical Strength and Rigidity

POM sheets offer excellent tensile strength and stiffness, making them ideal for load-bearing and precision parts in industrial applications.

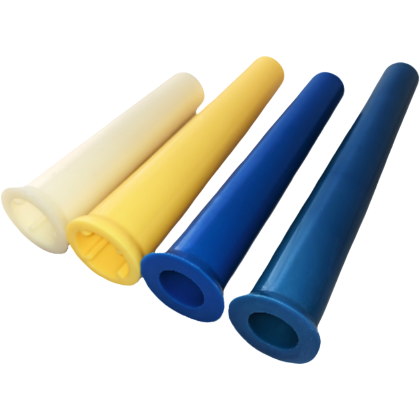

2.Outstanding Wear and Abrasion Resistance

With a naturally low coefficient of friction, POM sheets provide exceptional wear resistance, perfect for gears, bearings, and sliding components.

3.Excellent Dimensional Stability

Low moisture absorption and high crystallinity ensure precise tolerances and stable performance even in humid or changing environments.

4.High Fatigue and Impact Strength

POM maintains its properties under repeated stress and sudden impacts, outperforming many other engineering plastics.

5.Wide Operating Temperature Range

Typically usable from –40 °C to +100 °C (short-term up to 120 °C), making it versatile for diverse industrial settings.

6.Chemical Resistance

Resistant to fuels, solvents, and weak acids or alkalis; however, not recommended for use with strong acids or oxidizing agents.

7.Electrical Insulation Properties

POM sheets provide stable dielectric performance, suitable for electrical and electronic applications.

8.Food-Contact Grades Available

Certain grades comply with FDA/EU food safety standards, enabling use in food processing and packaging equipment.