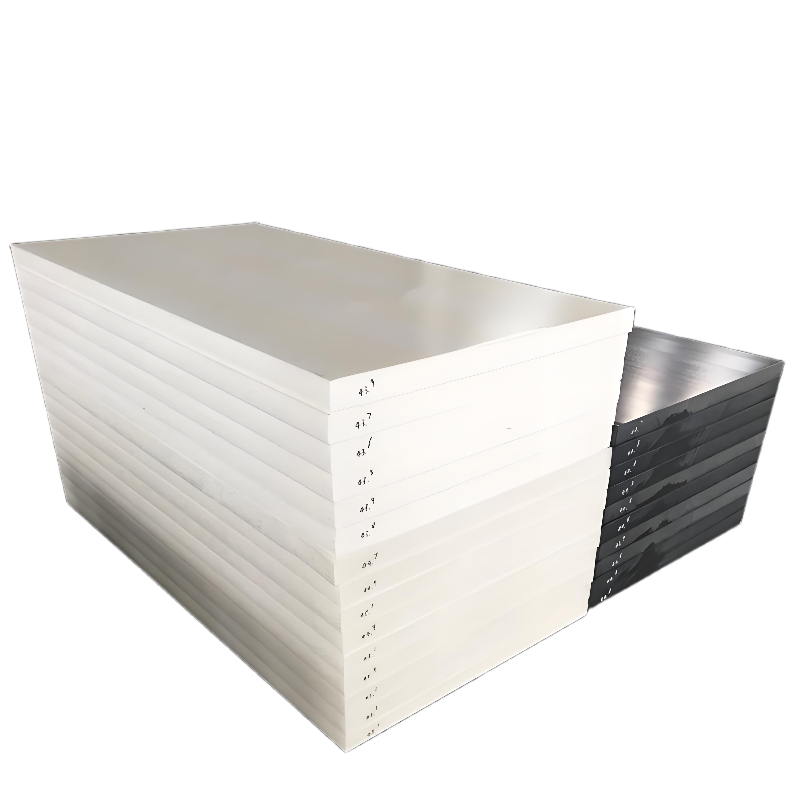

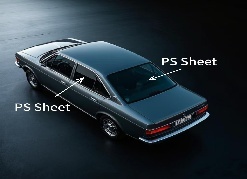

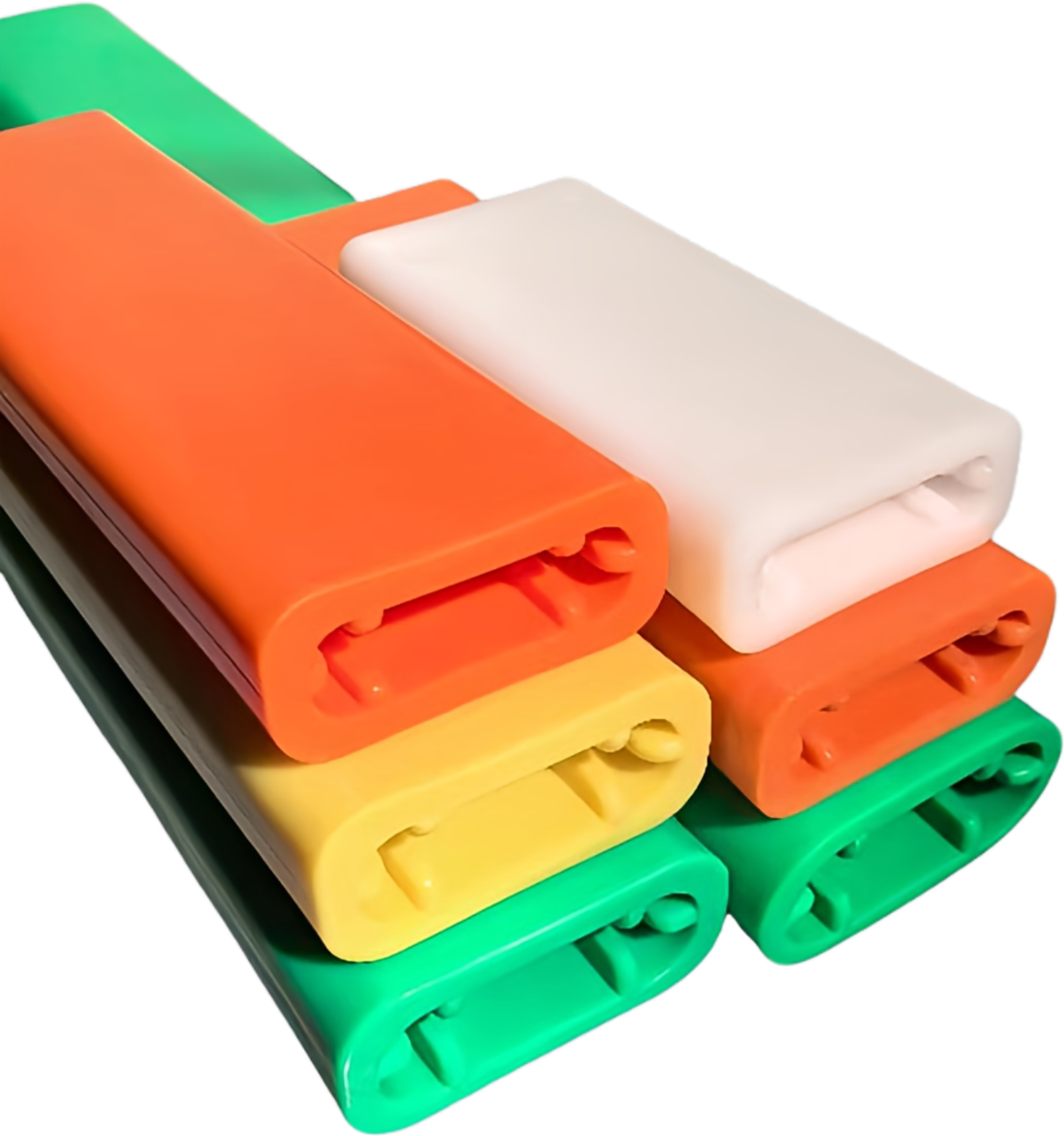

Color: White, beige Thickness: 2mm–200mm

Size: 1000x2000mm, 1220x2440mm, 1500x3000mm.

Custom Item: Color, Size

Advantage:

-

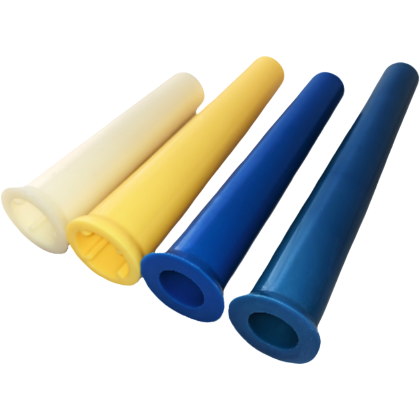

Excellent Chemical Resistance-Resists most acids, alkalis, salts, and organic solvents, making it an ideal alternative to metals in chemical, electroplating, and environmental industries.

-

Low Density and Lightweight-With a density of about 0.91–0.92 g/cm³, PP sheets are easy to handle, install, and transport, effectively reducing overall equipment weight.

-

Good Mechanical Strength-Offers a balanced combination of strength, rigidity, and toughness, suitable for various structural applications.

-

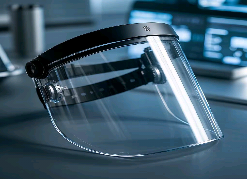

Outstanding Electrical Insulation-Non-conductive and moisture-resistant, ideal for use in electrical and electronic insulation components.

-

Non-toxic and Odorless-Meets food-grade safety standards, suitable for food processing, medical equipment, and drinking water tanks.

-

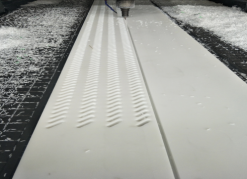

Excellent Processability-Easy to cut, drill, weld, and thermoform, allowing for the production of large or custom-shaped components.

-

Low Water Absorption-Water absorption rate below 0.01% within 24 hours, ensuring dimensional stability and no deformation in humid environments.