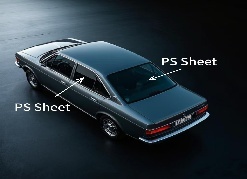

1.High Rigidity and Stiffness – PS sheets are lightweight yet maintain good structural strength for general applications.

2.Excellent Dimensional Stability – Maintains shape under normal temperature and humidity conditions.

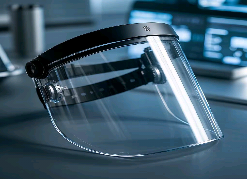

3.Good Optical Clarity – Transparent grades allow light transmission, suitable for displays and signage.

4.Lightweight – Easy to handle and install, reducing shipping and installation costs.

5.Electrical Insulation – Naturally non-conductive, suitable for certain electrical or electronic applications.

6.Ease of Fabrication – Can be cut, drilled, thermoformed, and printed with ease.

7.Cost-Effective – Offers an affordable solution for packaging, displays, and general-purpose panels.

8.Chemical Resistance – Resistant to mild acids and alkalis, though less resistant than PP or PE.

9.Surface Finish Options – Smooth, matte, or textured surfaces available depending on application.