Polysulfone (PSU) Sheet

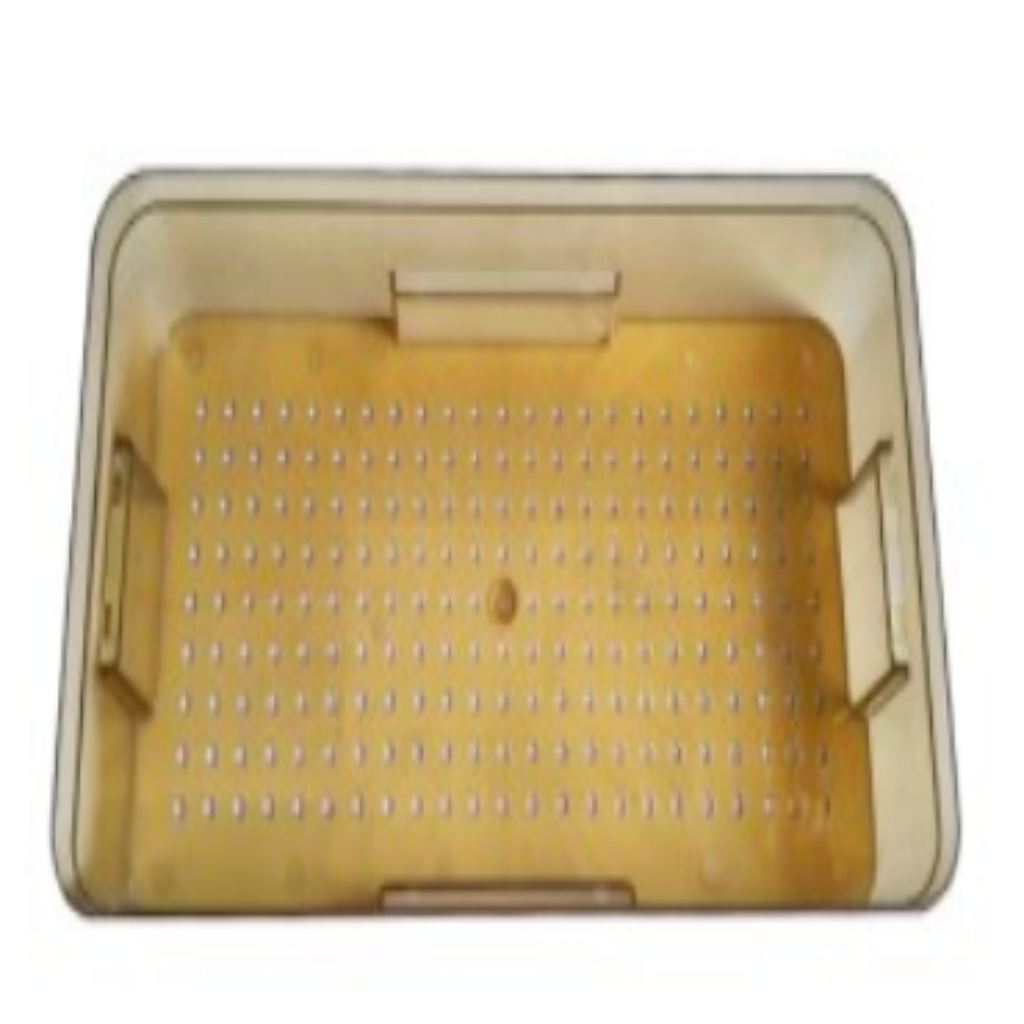

1.Outstanding Heat Resistance – PSU sheets can continuously operate at temperatures up to 160–170 °C, far exceeding many conventional plastics. This makes them suitable for hot water, steam sterilization, and demanding thermal environments.

2.Excellent Hydrolysis & Steam Resistance – Unlike many engineering plastics, PSU maintains its mechanical integrity even after repeated exposure to hot water and pressurized steam, ideal for medical and food-related applications.

3.High Mechanical Strength & Toughness – PSU sheets combine rigidity with impact resistance, offering stable performance under load and reducing the risk of cracking or deformation.

4.Good Dimensional Stability – With low creep and minimal warpage under stress or heat, PSU ensures long-term accuracy in precision components.

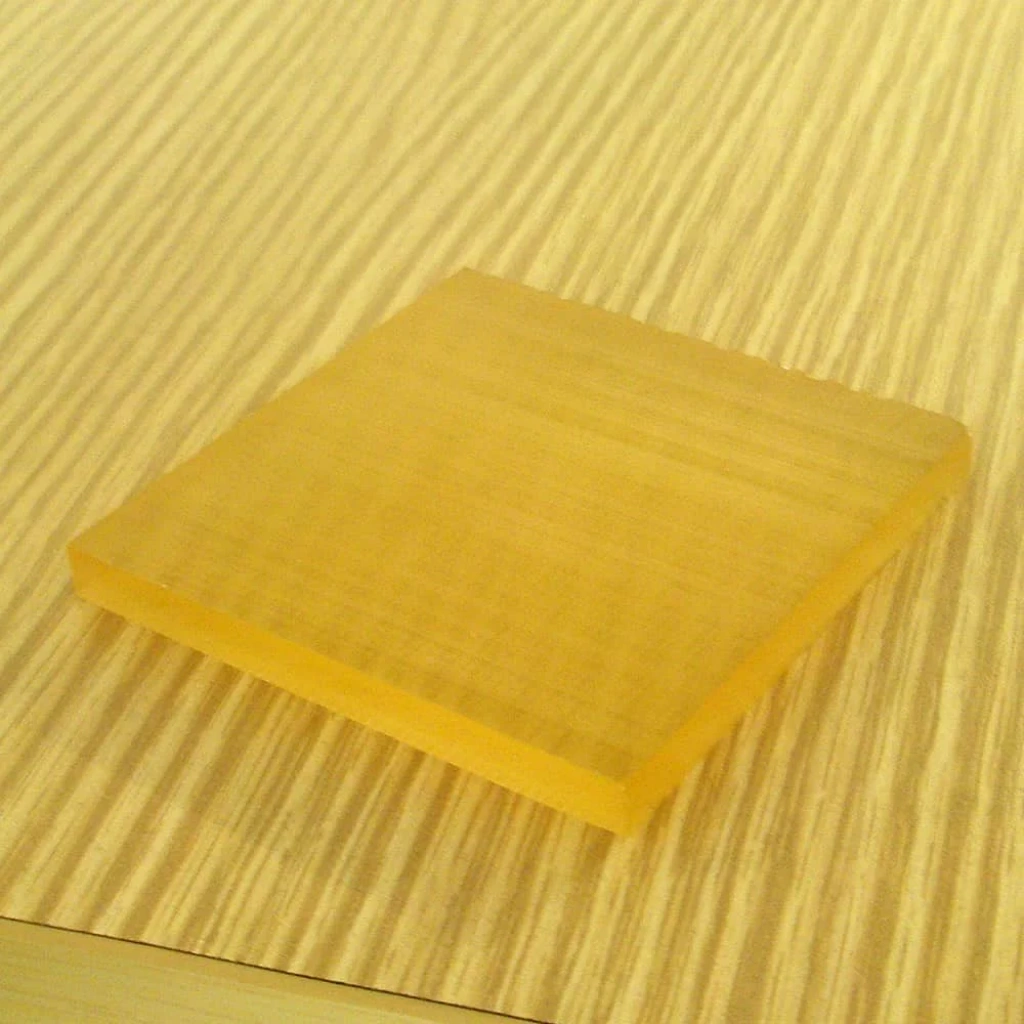

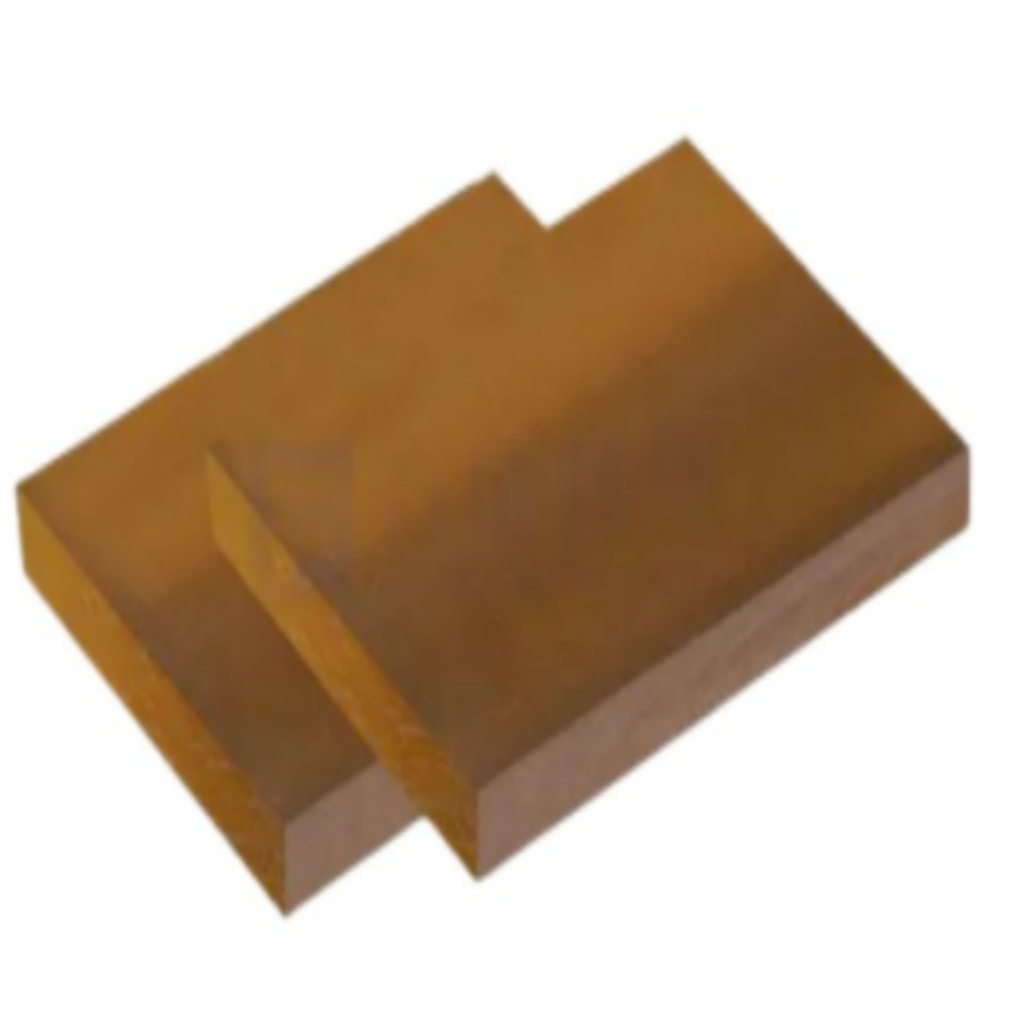

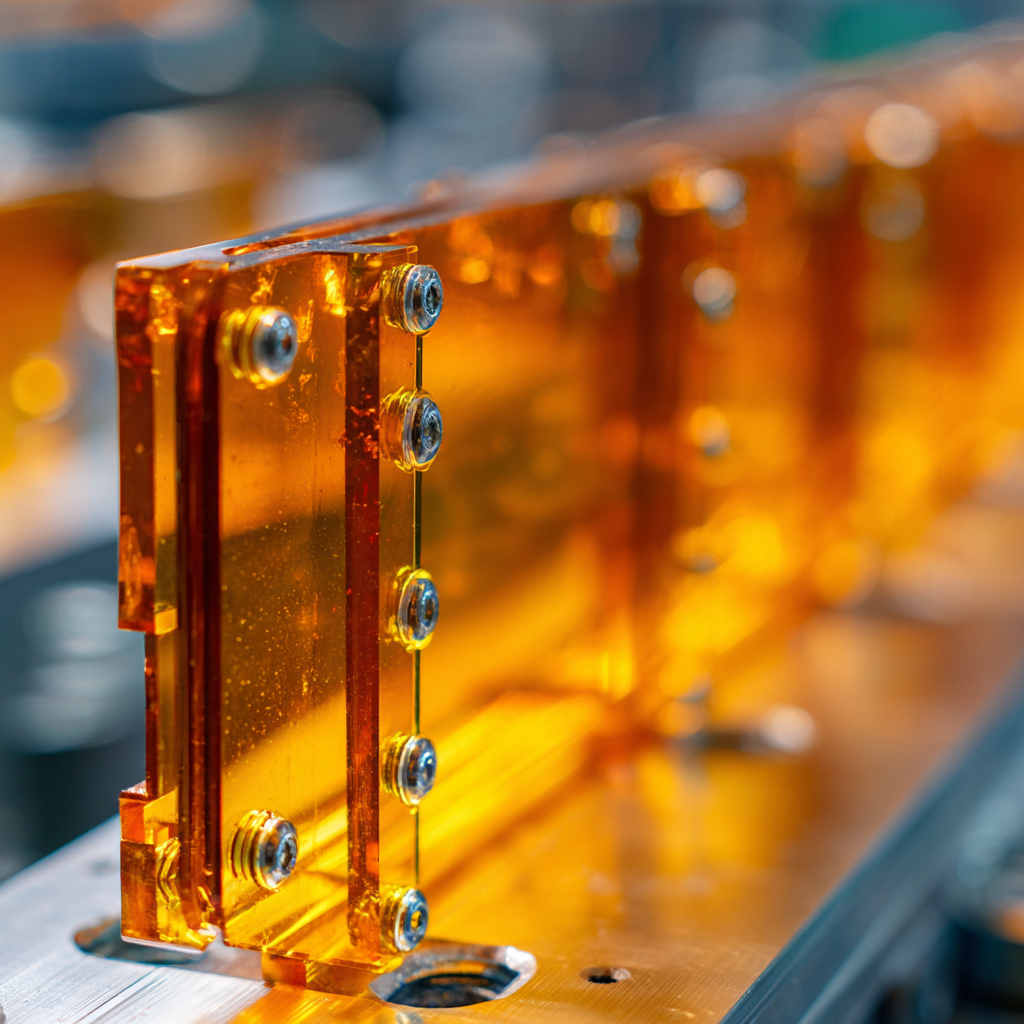

5.Transparency & Aesthetic Appeal – PSU sheets are naturally amber-transparent, offering both functional and aesthetic advantages compared to opaque engineering plastics.

6.Excellent Electrical Insulation Properties – Provides reliable dielectric strength, making it suitable for electrical and electronic device components.

7.Biocompatible & Food-Safe – Widely used in medical devices, laboratory equipment, and food processing machinery, PSU is compliant with many international safety standards.

8.Chemical Resistance – Resists mineral acids, alkalis, and many cleaning agents, ensuring durability in harsh industrial and sterilization environments.