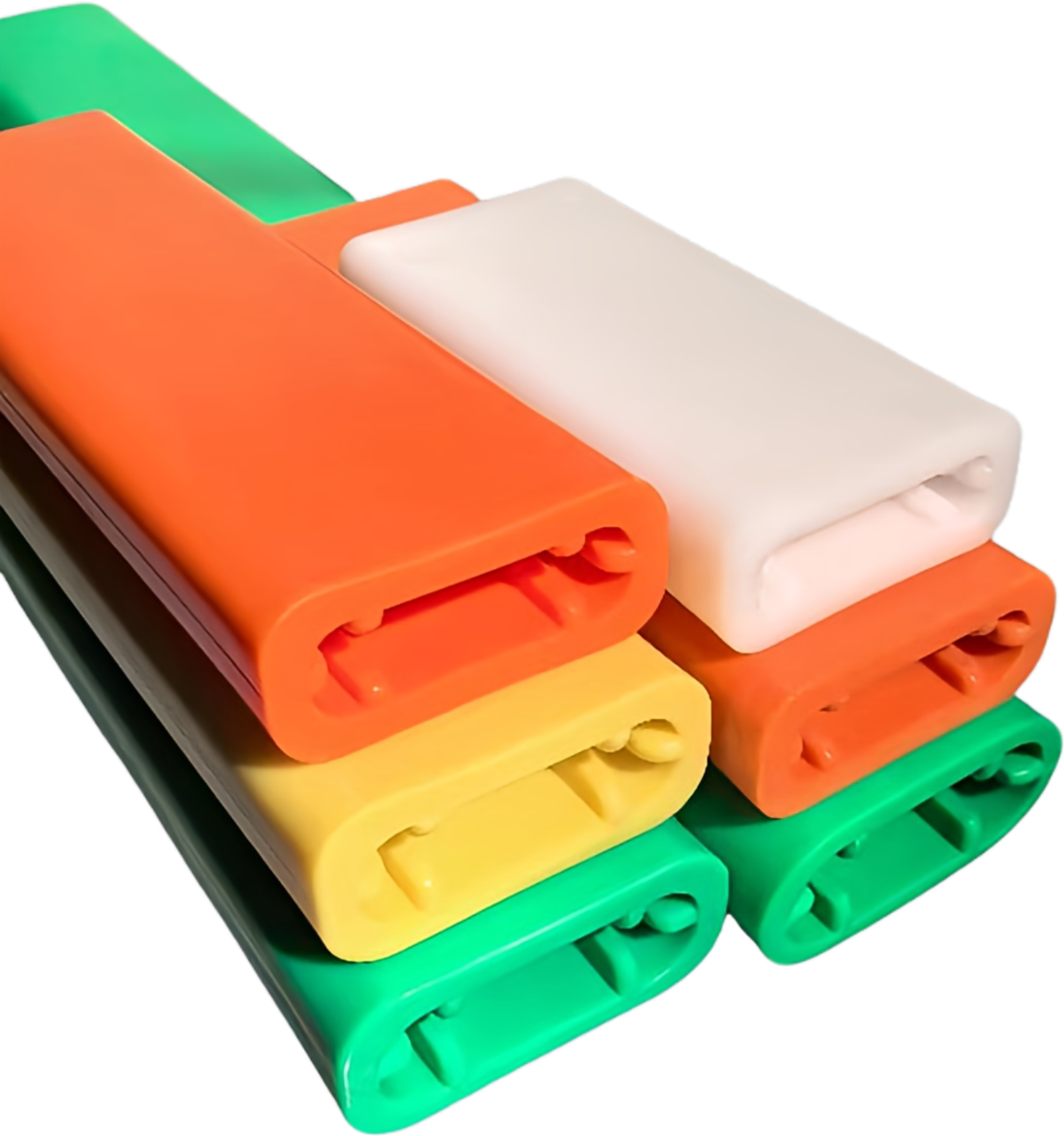

Polyurethane (PU) Sheet

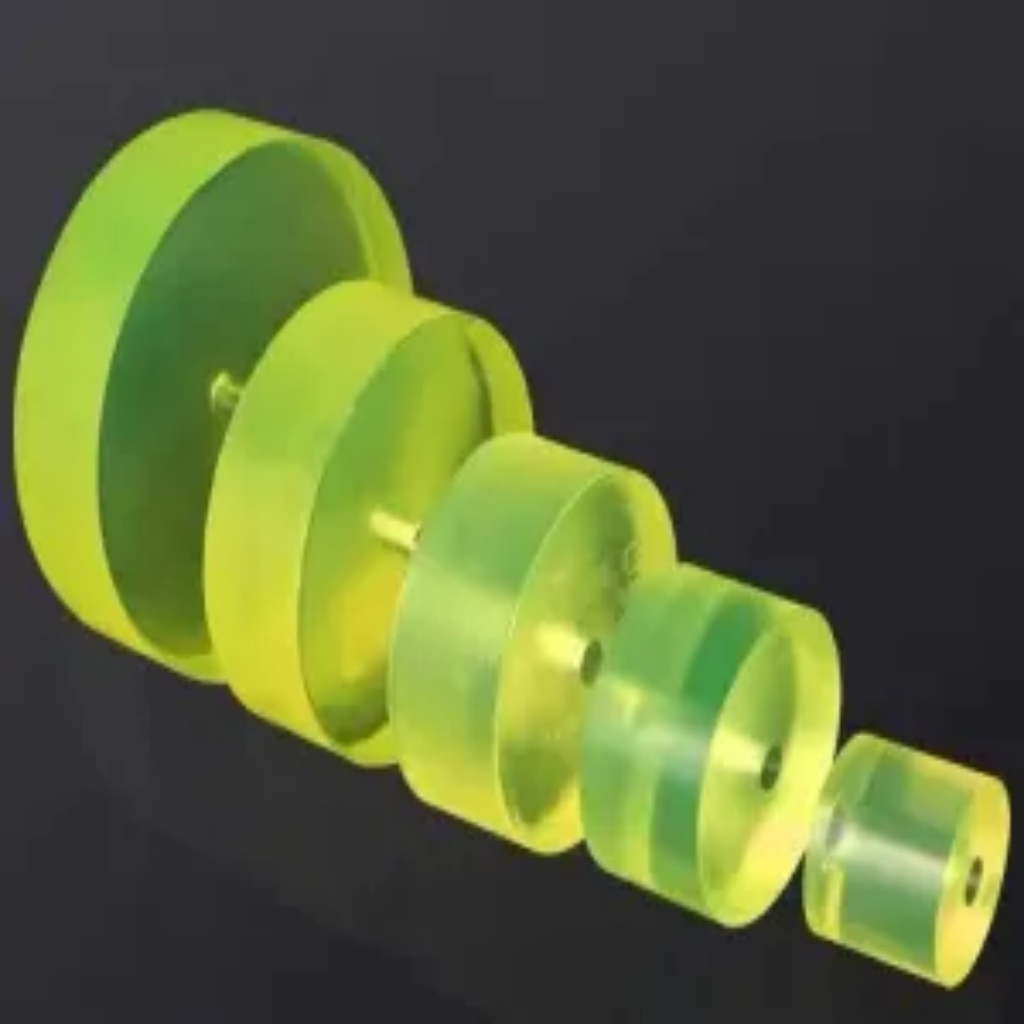

1.Outstanding Wear Resistance – PU sheets offer exceptional abrasion resistance, making them ideal for high-friction and heavy-load applications such as rollers, seals, and impact pads.

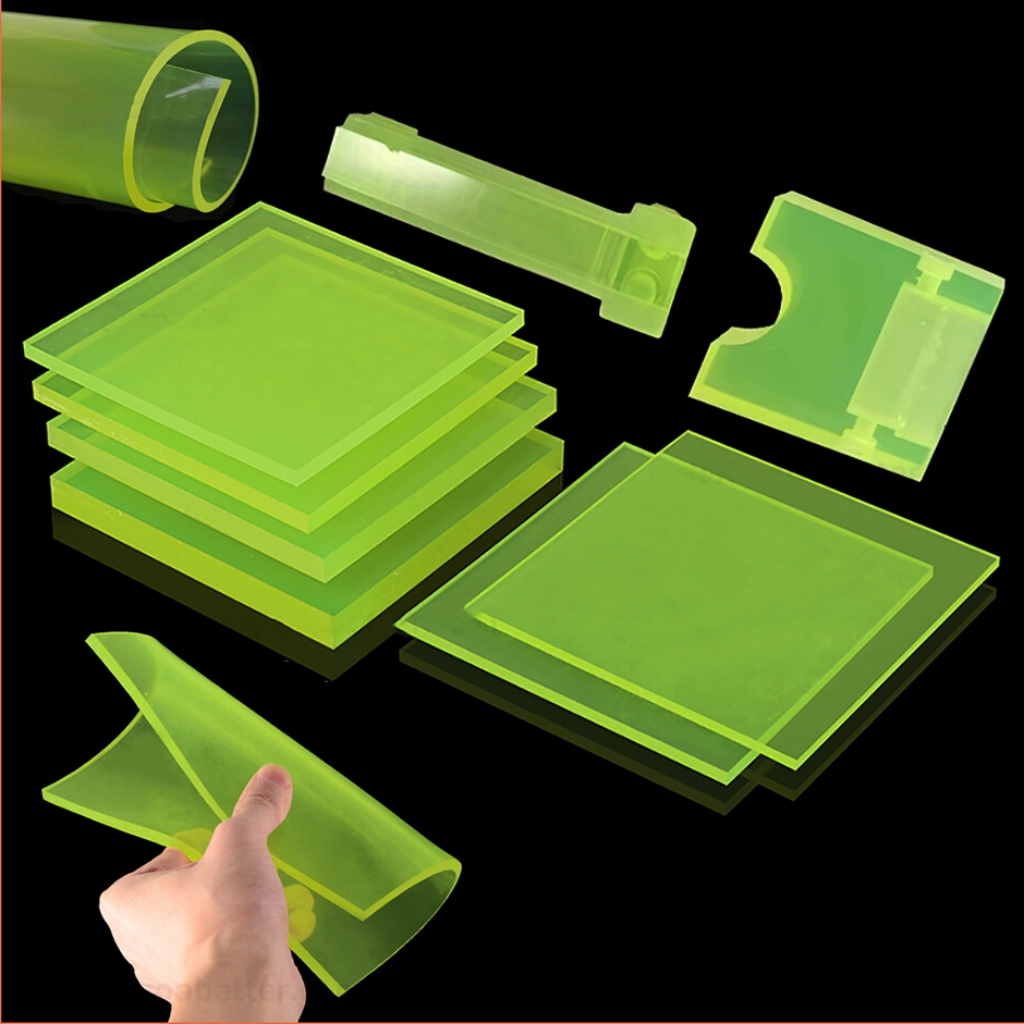

2.High Impact Strength & Elasticity – Combines toughness with flexibility, allowing PU boards to absorb shocks and vibrations without cracking.

3.Excellent Load-Bearing Capacity – Maintains mechanical strength under continuous stress, suitable for dynamic and structural applications.

4.Wide Hardness Range – Available in soft, flexible grades to rigid, hard types, enabling customization for diverse industrial needs.

5.Good Chemical Resistance – Resistant to oils, greases, and many solvents, ensuring reliable performance in mechanical and chemical environments.

6.Low Noise & Vibration Dampening – Naturally reduces operational noise and mechanical vibration, enhancing equipment lifespan.

7.Temperature Resistance – Performs well in a broad temperature range (typically -40 °C to +80 °C), with specialty grades extending beyond.

8.Cost-Effective Performance – Offers a balance of wear resistance, flexibility, and mechanical strength at a reasonable cost compared with metals and other engineering plastics.