1.High Chemical Resistance – Excellent resistance to acids, alkalis, salts, and many industrial chemicals, making it suitable for chemical processing and storage applications.

2.Good Mechanical Strength & Rigidity – Stiff and durable, able to maintain shape under load and temperature variations.

3.Flame Retardant – Naturally self-extinguishing with good fire performance compared to many other plastics.

4.Excellent Dimensional Stability – Retains shape and size even under fluctuating temperatures and humidity.

5.Good Electrical Insulation – Non-conductive, widely used for electrical paneling and insulating components.

6.Easy to Fabricate – Can be cut, welded, machined, drilled, and thermoformed to suit various applications.

7.Weather & Corrosion Resistance – Suitable for indoor and outdoor use with good resistance to moisture and UV exposure (with stabilizers).

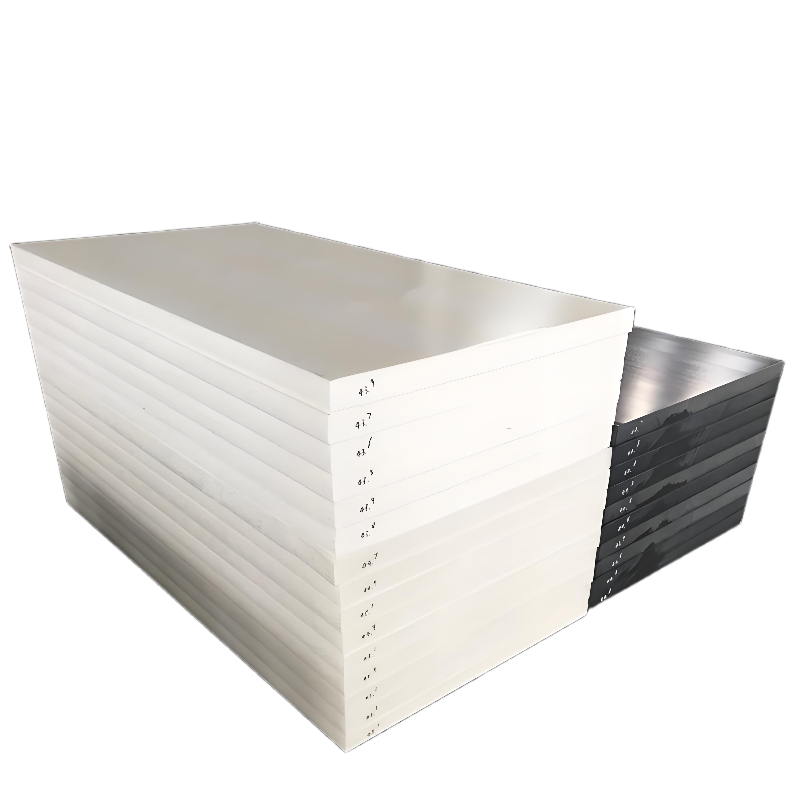

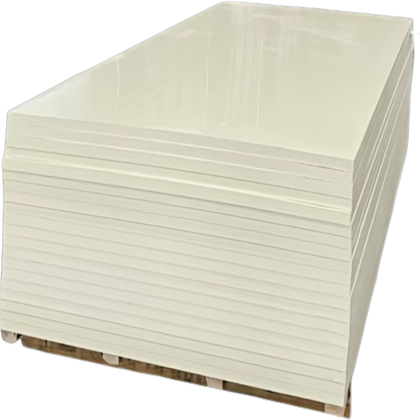

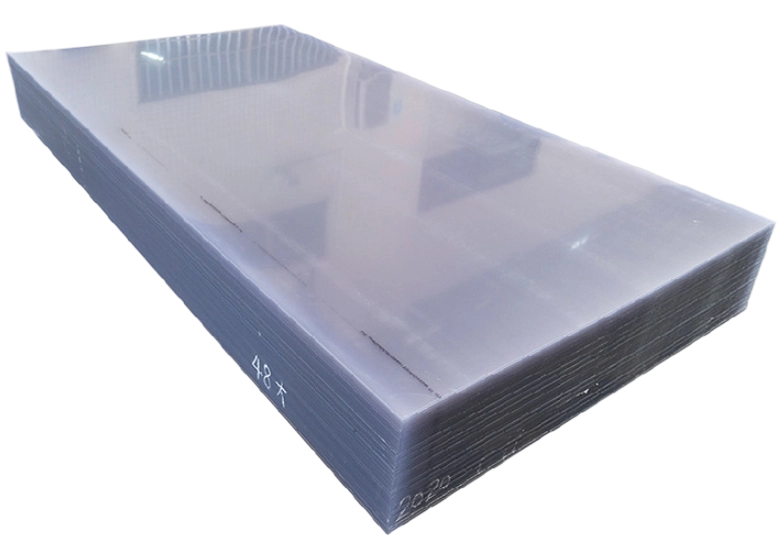

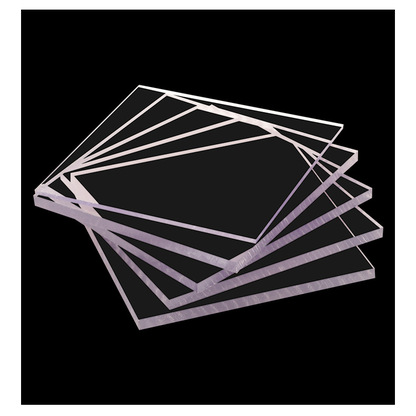

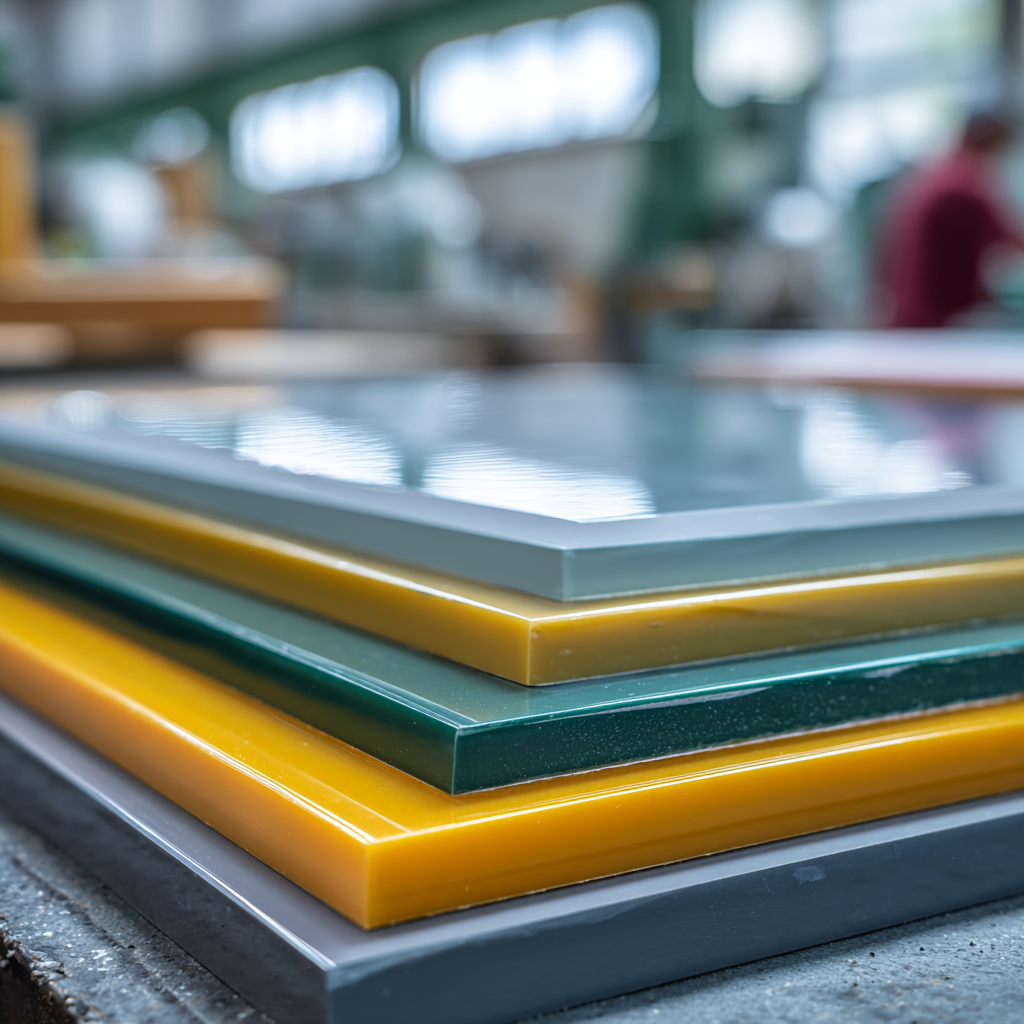

8.Variety of Surface Finishes – Smooth, matte, or textured surfaces available to meet functional or aesthetic needs.

9.Wide Range of Grades – Available in rigid PVC sheets for structural use and flexible PVC sheets for cushioning or lining applications.

10.Cost-Effective – Combines performance and affordability for industrial, commercial, and construction sectors.