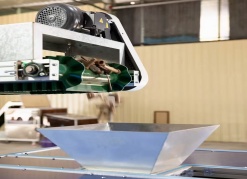

Sorters Equipment

Total power: 1 kW

Rated voltage: 220V

Total weight: 600KG

Output: 500KG-600KG/H

Total power: 1 kW

Rated voltage: 220V

Total weight: 600KG

Output: 500KG-600KG/H

| Cost Analysis of Sorters VS Labor | |||

| Performance | Sorting Machine | Manual Sorting | Comparison Results |

| Efficiency | 500-600kg/h | One person/day 300kg | One unit/day is equivalent to 16 people’s workload |

| Cost | Take the minimum value to 8h to calculate sorting 4.8 tons / day | Per capita wage ¥150/day | Wage per person = ¥150 * 16 people = ¥2400 |

| Accuracy | Simultaneous sorting of 8 kinds of accessories/accurate counting | Repetitive and boring/easy to confuse | More efficient and accurate |

| Convenience | Automatic loading/intelligent counting | Slow pace of manual labor/low efficiency | Improve working efficiency and reduce management cost |

| Environmentally Friendly | More organized, more smooth, no pollution | Back and forth handling and stacking | Cleaner workshop environment |

1.Conveying system

Sorters Equipment usually consists of belt conveyor, chain conveyor or roller conveyor, etc. It is responsible for smoothly conveying the metal parts to the sorting area, and ensuring that the parts pass through the sorting equipment at a suitable speed and spacing.

2.Detection system

Including all kinds of sensors and detection equipment, such as photoelectric sensors, laser sensors, visual detection systems, etc., used to obtain the characteristics of the metal parts of the information, such as shape, size, color, location, etc., to provide a basis for sorting.

3.Control system

Generally consists of computers, programmable logic controllers (PLC), etc. It processes and analyzes the information acquired by the detection system, sends out control instructions to the sorting actuators according to the preset sorting rules, coordinates the work of each part, and realizes accurate sorting.

1.Fast sorting speed, high work efficiency.

2.Precise identification, low sorting error rate.

3.Continuous and stable operation, reliable performance.

4.It can reduce labor cost and improve production efficiency.

5.Reduce the risk of work injury, perfect safety protection.

6.Multi-parameter sorting, strong adaptability.

7.Can quickly switch sorting mode, high flexibility.

8.With data recording function, convenient for production management and quality traceability.

1.Manufacturing industry

Sorters Equipment used to sort metal fittings in the production process of automotive engines, transmissions and other components, such as bolts, nuts, gaskets, etc., to ensure the quality of the fittings and the accuracy of the assembly.

2.Electronic manufacturing industry

Sorting metal pins, connectors, shields and other accessories in electronic equipment to ensure the quality and performance of electronic components and improve the production efficiency and reliability of electronic products.

3.Hardware processing industry

In the production of various types of hardware products, metal stamping parts, forging parts, machining parts, etc. for sorting, according to the size, shape, surface quality and other requirements for classification, to facilitate subsequent processing and assembly.

4.Recycling and processing industry

Sorters Equipment is used in the recycling and sorting of scrap metal, separating different kinds of metal, realizing effective recycling and reuse of resources, and improving the recycling value of scrap metal.

Sorters Equipment is intelligent and fully automatic sorter.

The sorters equipment accuracy rate is 100%.

The equipment has no wearing parts under normal use.

Sorters Equipment is applicable to the objects with length <150mm; thickness 35mm and size within 80mm*80mm.

We can customize according to the customer’s materials, such as the number of sorting ports, the type of sorting materials and so on.

Sorters Equipment can count 1~9999 pieces.

Sorting machine 500KG, loading machine 40KG, feeder 60KG, total 600KG.

Guangdong Chuangiangshu New Materials Co.,Ltd

Guangdong Chuangiangshu New Materials Co.,Ltd

No.9, Lane 1, Heng Jiang Nan San Yuan, Shatou Street, Panyu District, Guangzhou, China

Contact Number: +86 189 2759 8228

Email: edison@nmtplastics.com

WhatsApp: +86 189 2759 8228