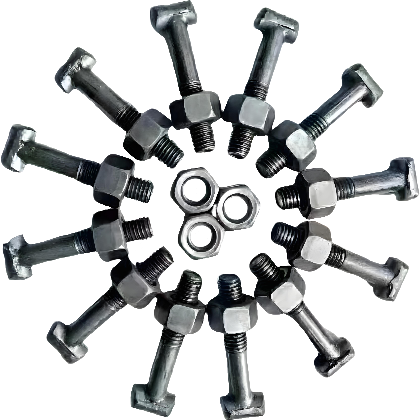

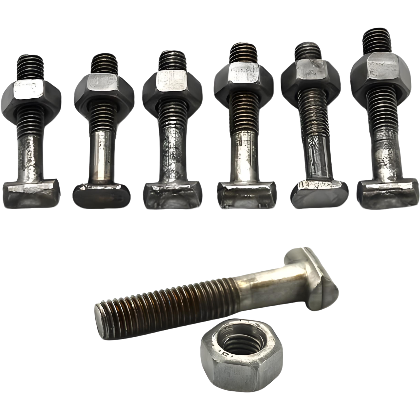

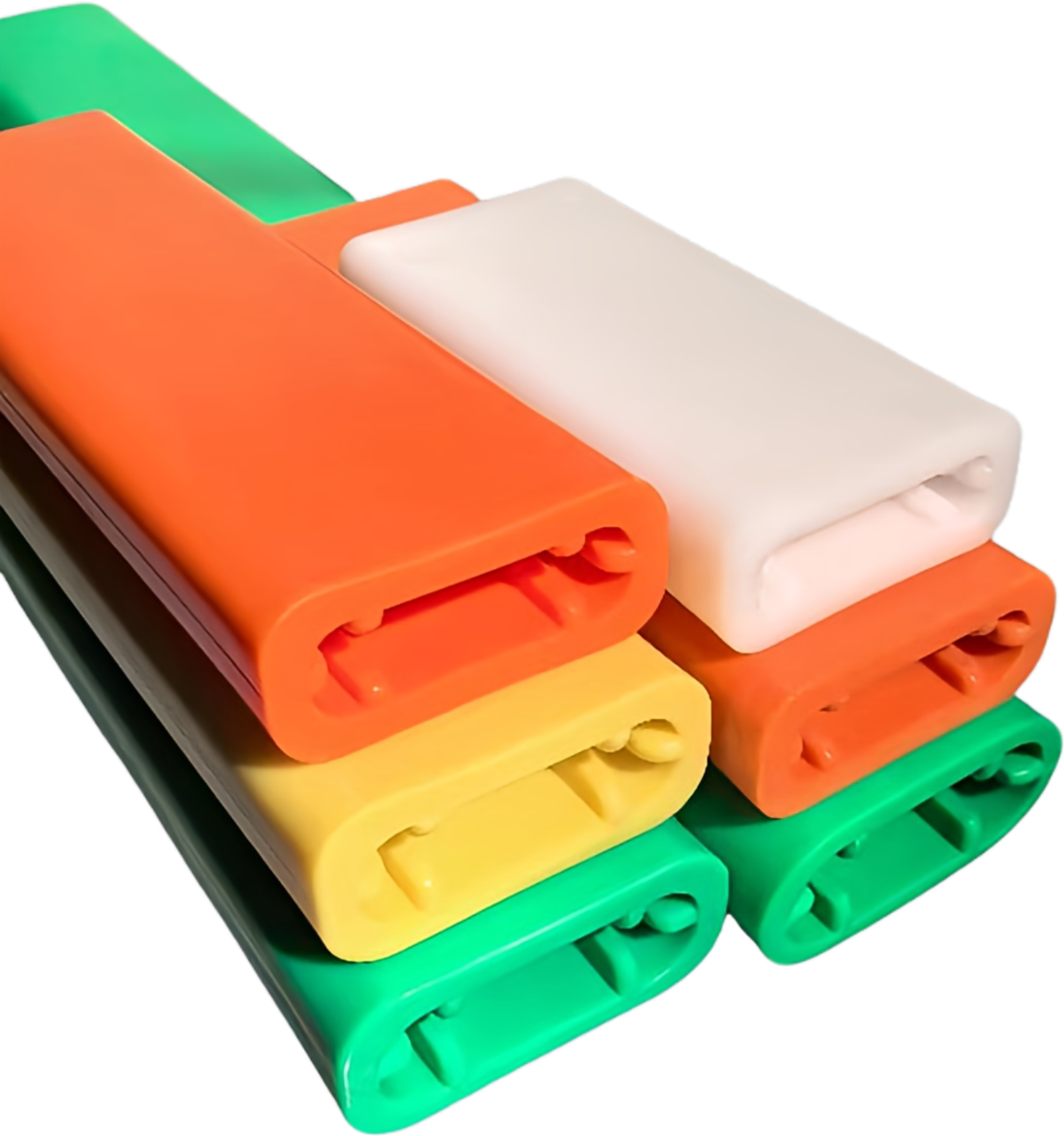

T-Screw

1. Convenient installation, simple operation, improve construction efficiency.

2. Match with aluminum mold, accurate positioning of the template, to ensure the accuracy of the building.

3. Made of high-strength steel, durable and can be turned over many times, reducing costs.

4.T-shaped head and aluminum mold slot fit, connecting firmly, anti-template shift.