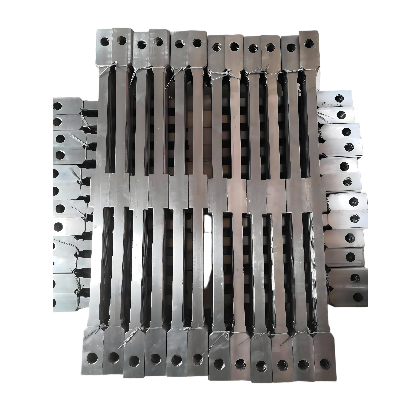

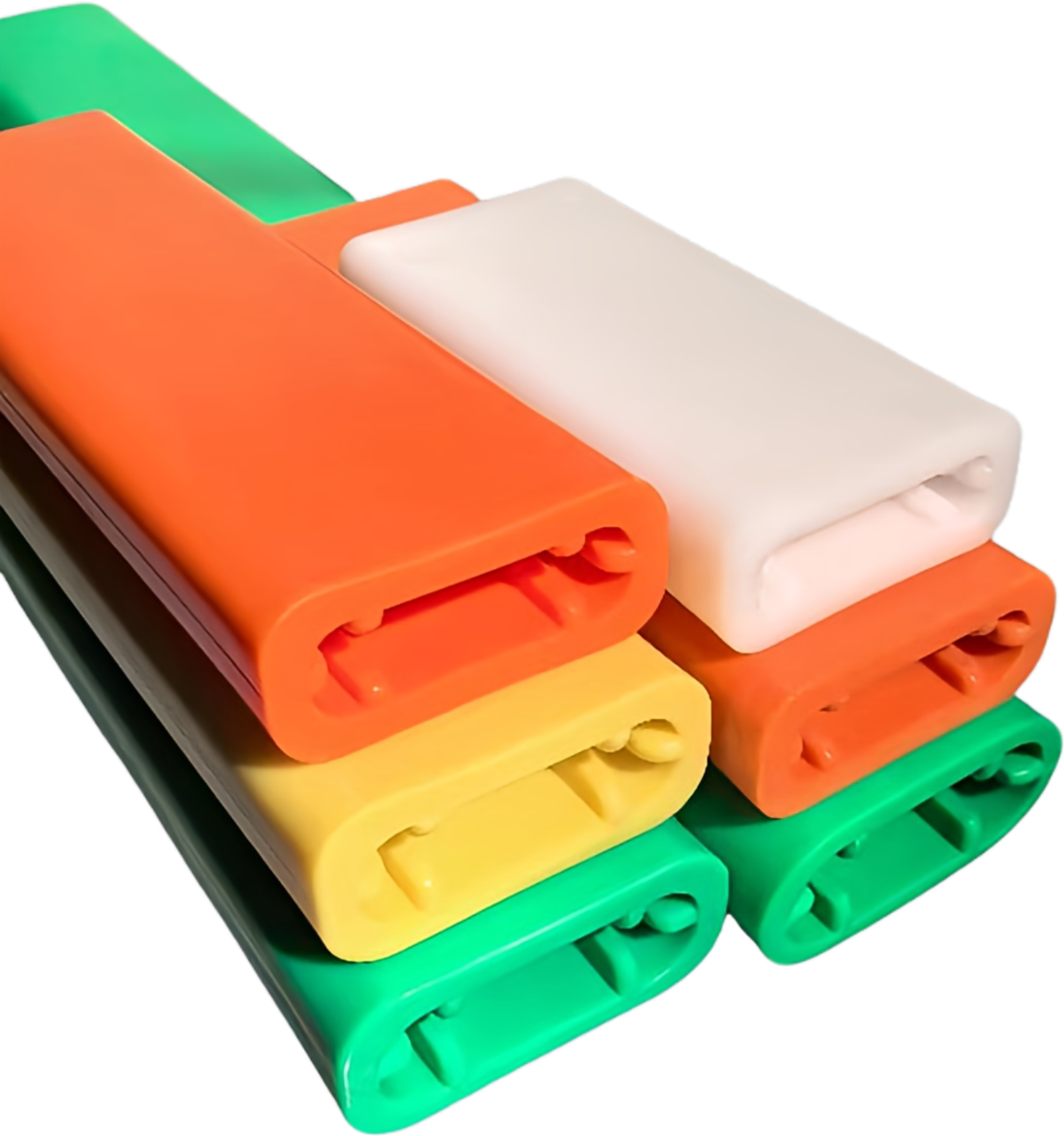

Tie Plate

1. Simple operation, quick installation, saving construction time.

2. The material is sturdy and can withstand large tensile force, effectively preventing deformation of formwork.

3. Compared with the traditional screw system, it reduces the use of components and saves cost.

4. after demolding, there is no screw hole on the wall surface, which reduces the later repair work and makes the wall surface more flat and beautiful.