1.Chemical Industry – Used for chute liners, hoppers, conveyors, and chemical handling parts thanks to outstanding chemical and abrasion resistance.

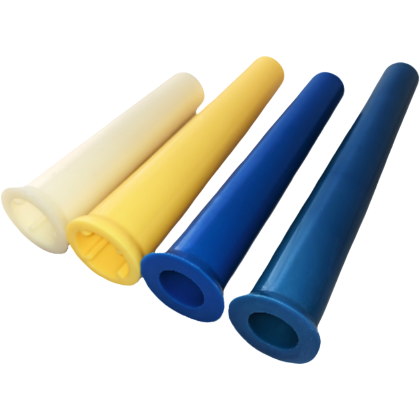

2.Water Treatment & Environmental Projects – Ideal for sliding components, wear strips, and lining in sewage, marine, and water treatment facilities due to its low moisture absorption.

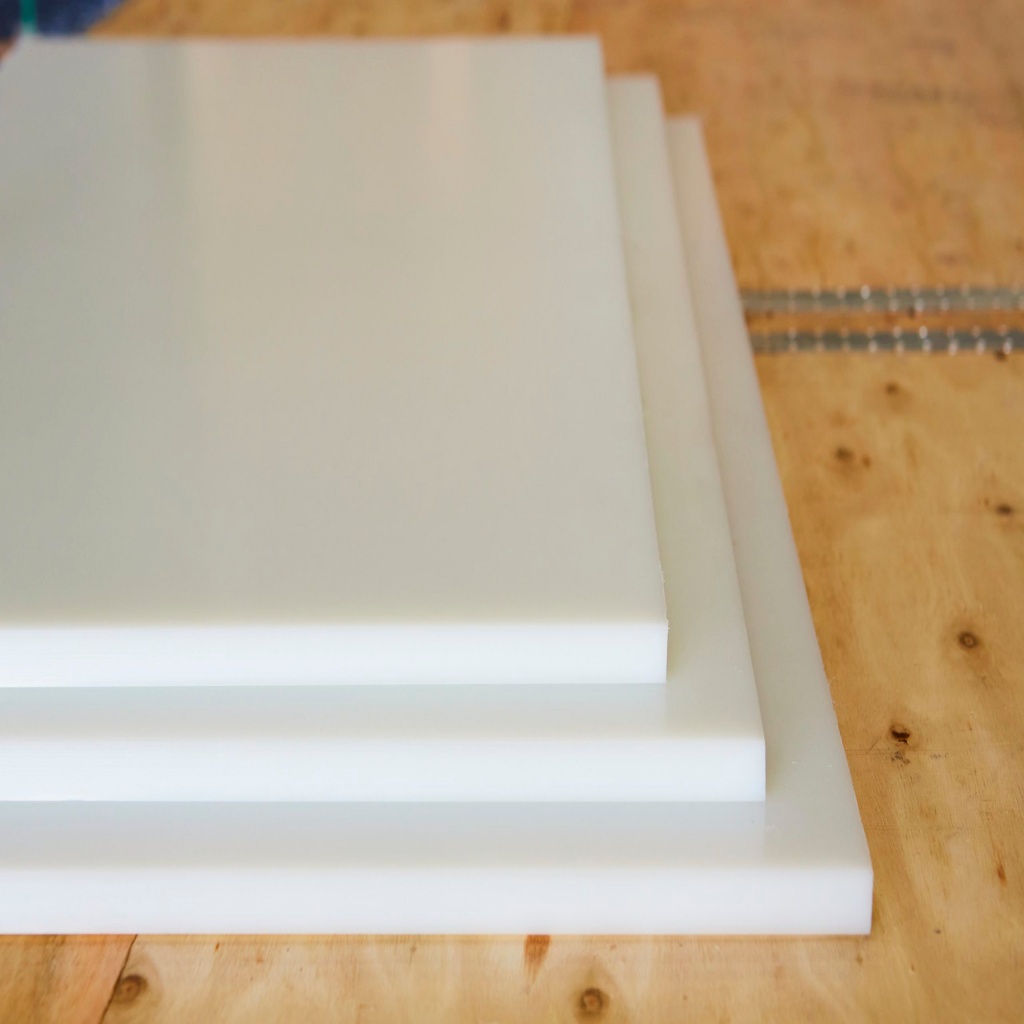

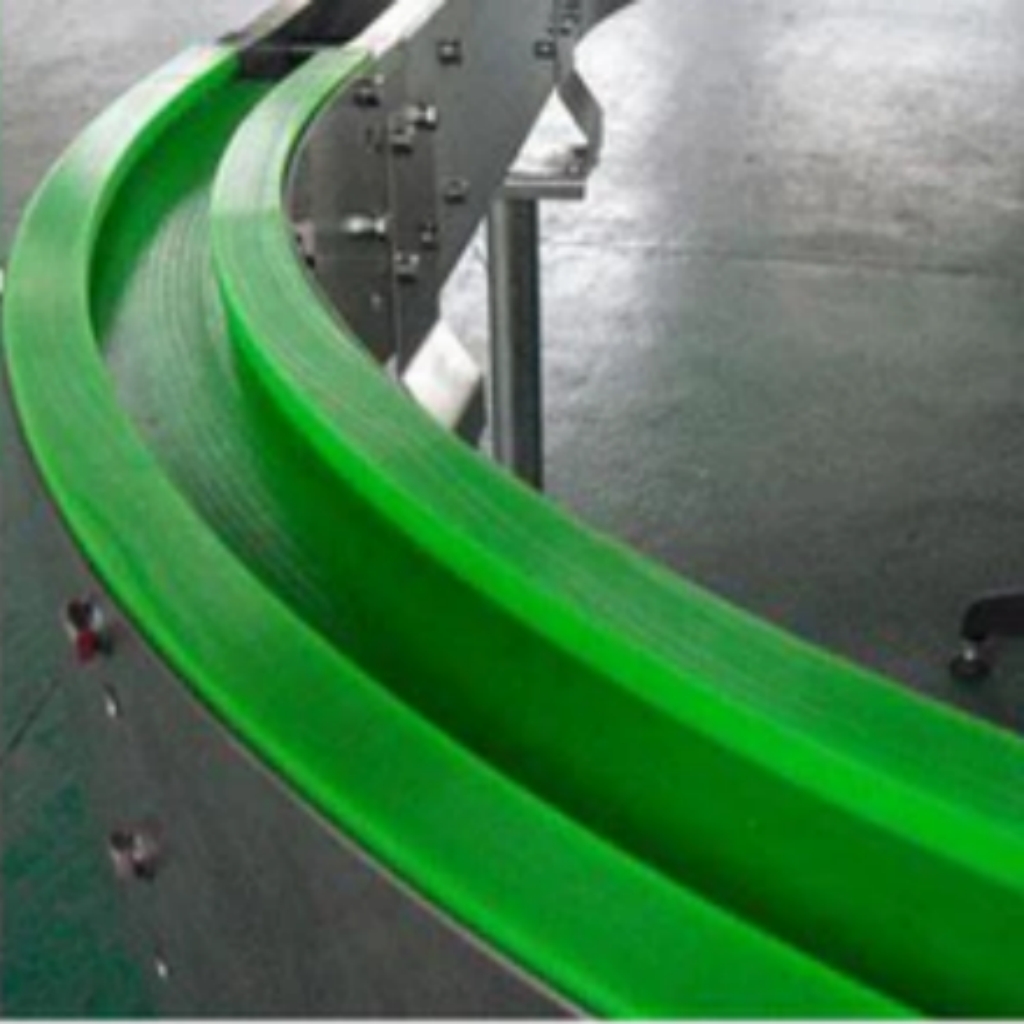

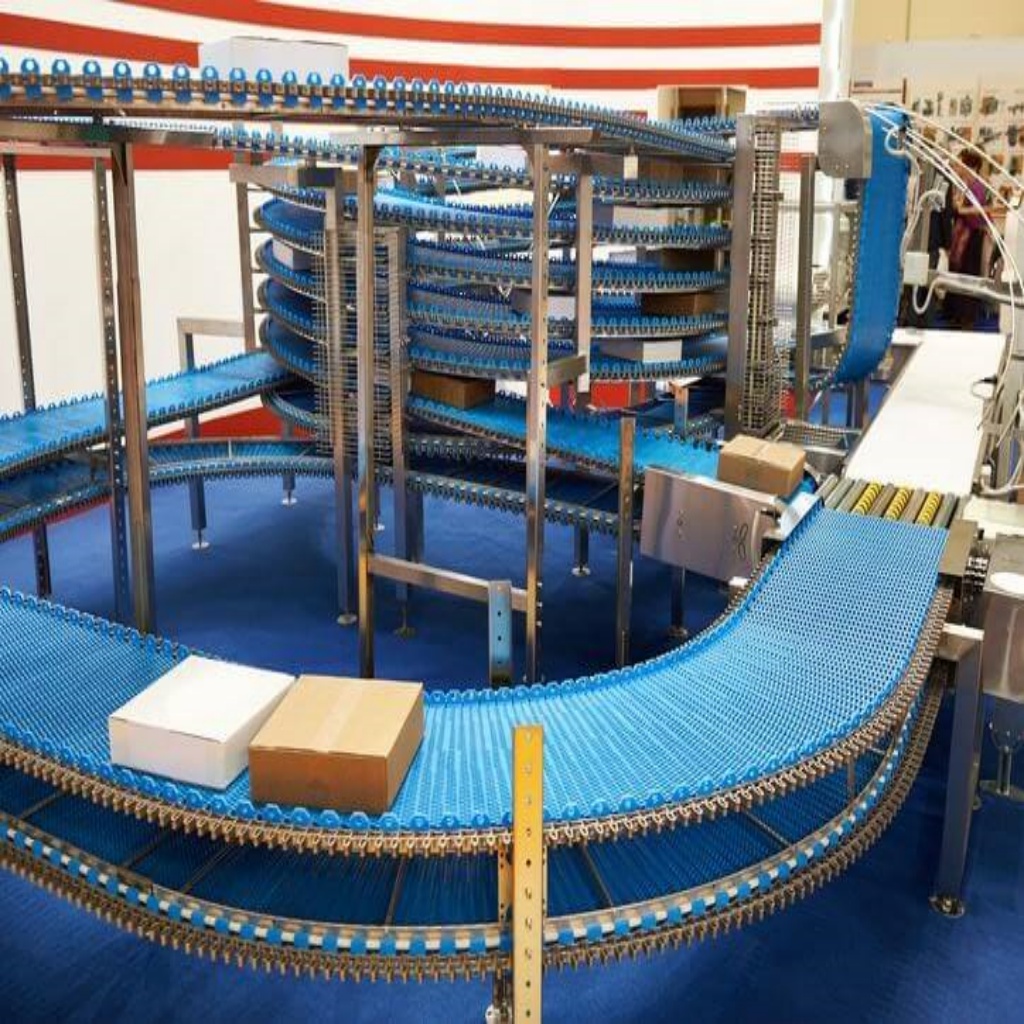

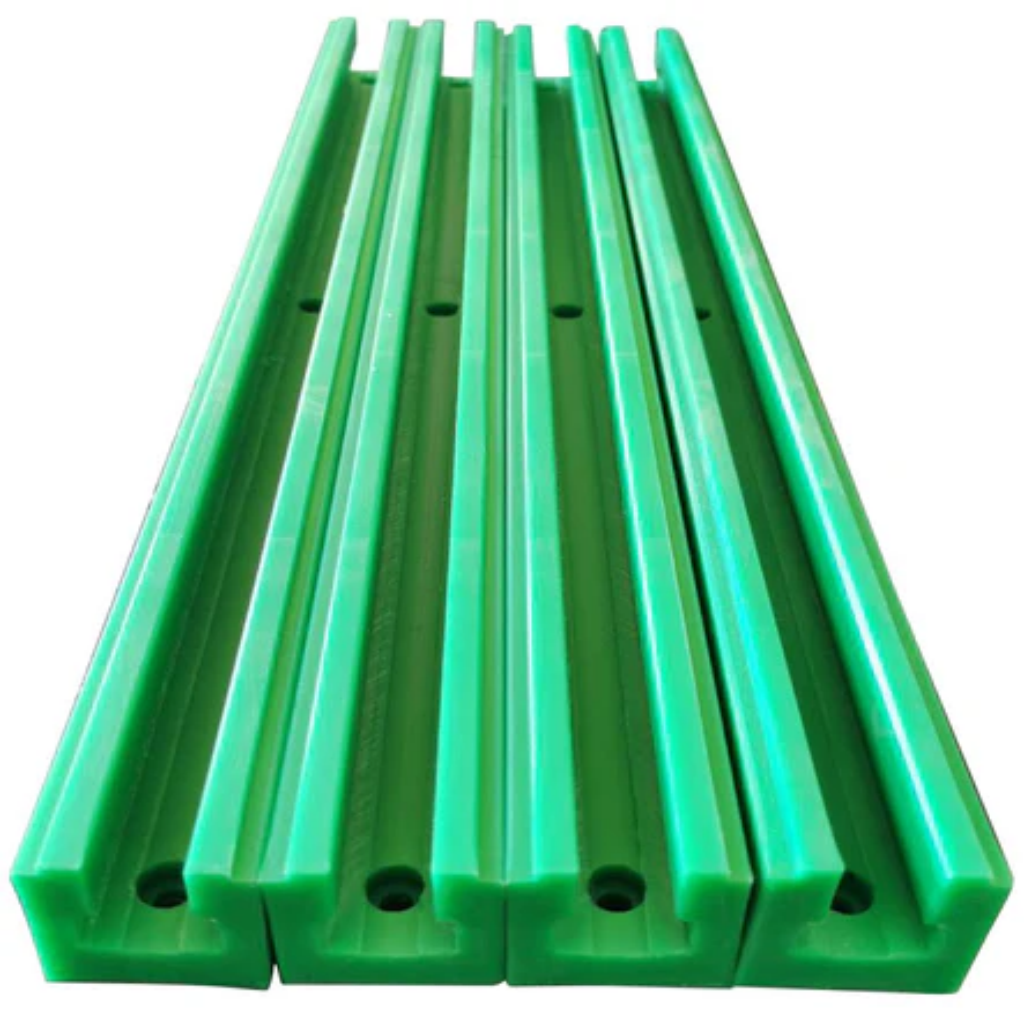

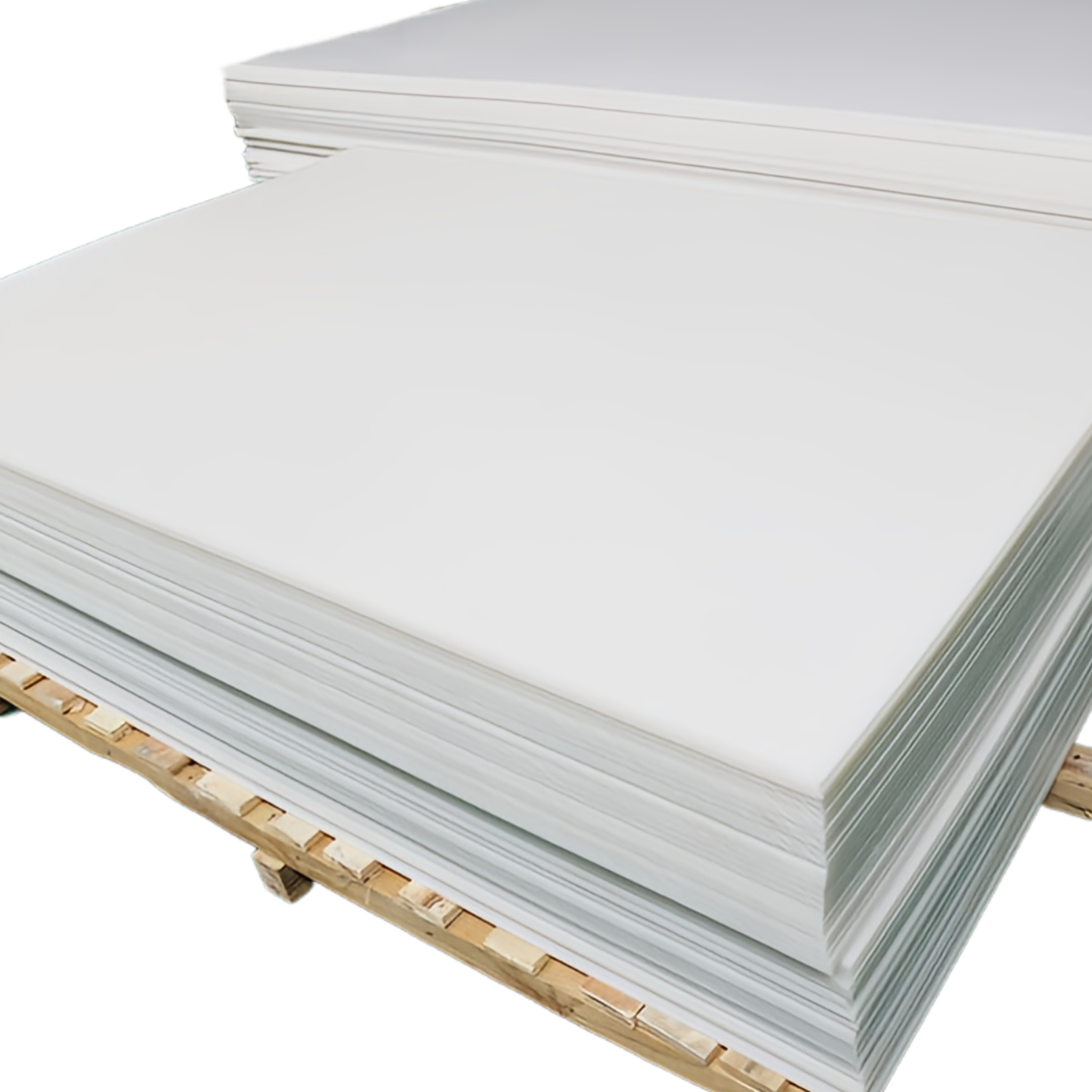

3.Food Processing & Packaging – Commonly used for cutting boards, conveyor guides, star wheels, and processing table surfaces since it is FDA-approved, non-toxic, and hygienic.

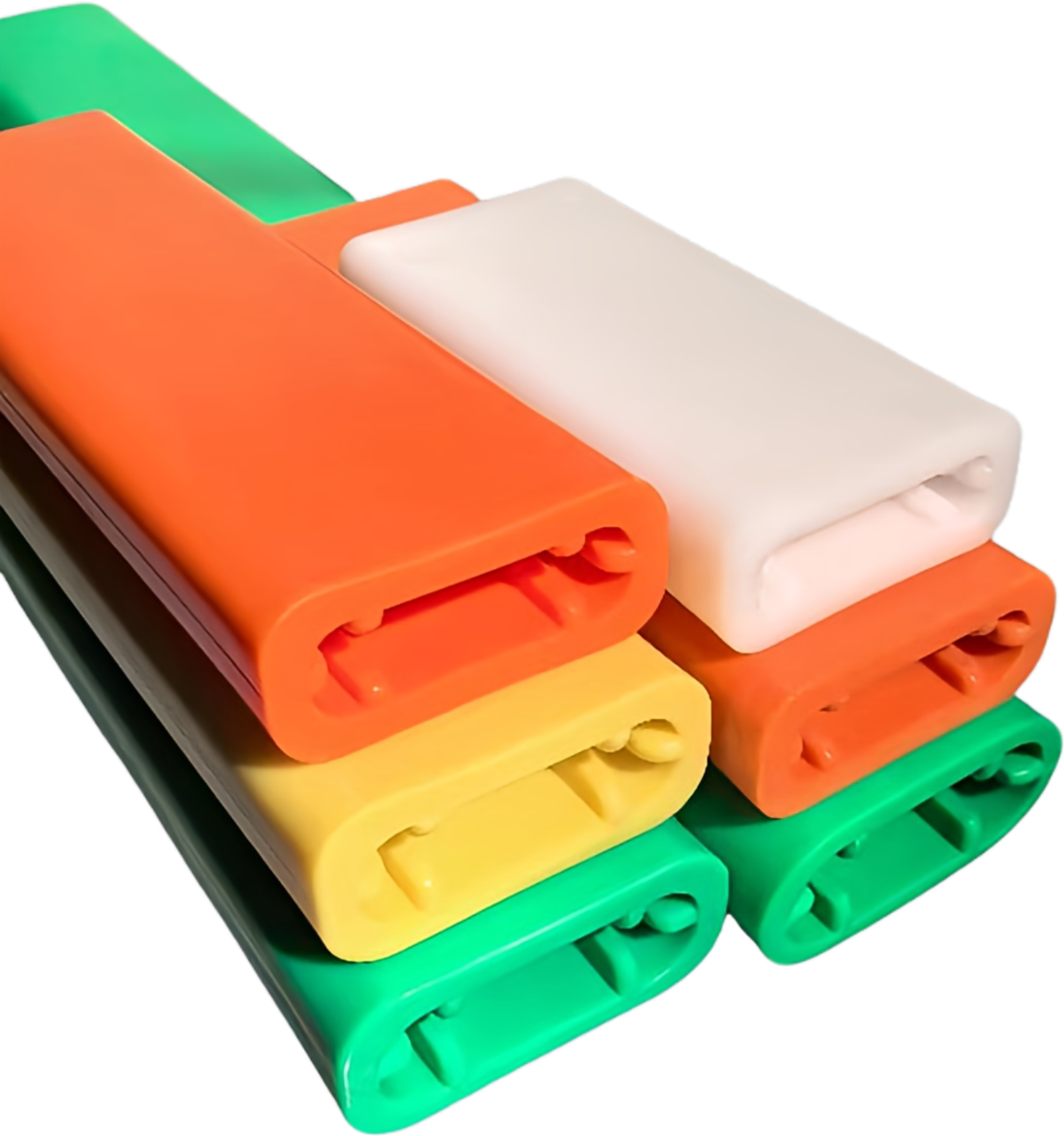

4.Automotive & Transportation – Applied in truck liners, fenders, bumpers, and protective panels where high impact strength and wear resistance are required.

5.Construction & Building – Utilized as sliding pads, impact plates, dock bumpers, and protective barriers in high-wear zones.

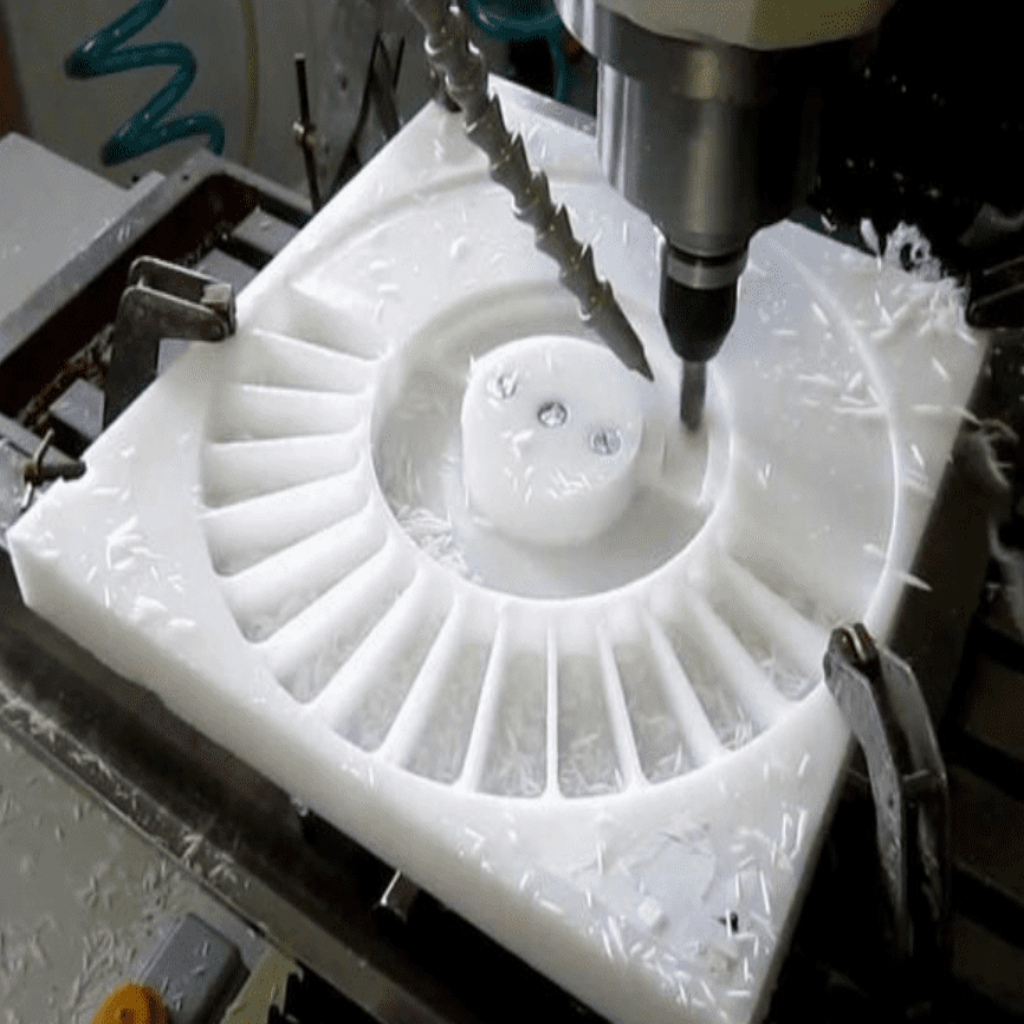

6.Electronics & Industrial Equipment – Fabricated into gears, bearings, rollers, and wear strips with self-lubricating properties for smooth operation.

7.Mining & Material Handling – Extensively used for liners in silos, hoppers, coal chutes, and conveyor systems, preventing material sticking and reducing maintenance.

8.Marine & Dock Applications – Suitable for dock fenders, pier protection, and ship components due to excellent impact resistance and resistance to saltwater.