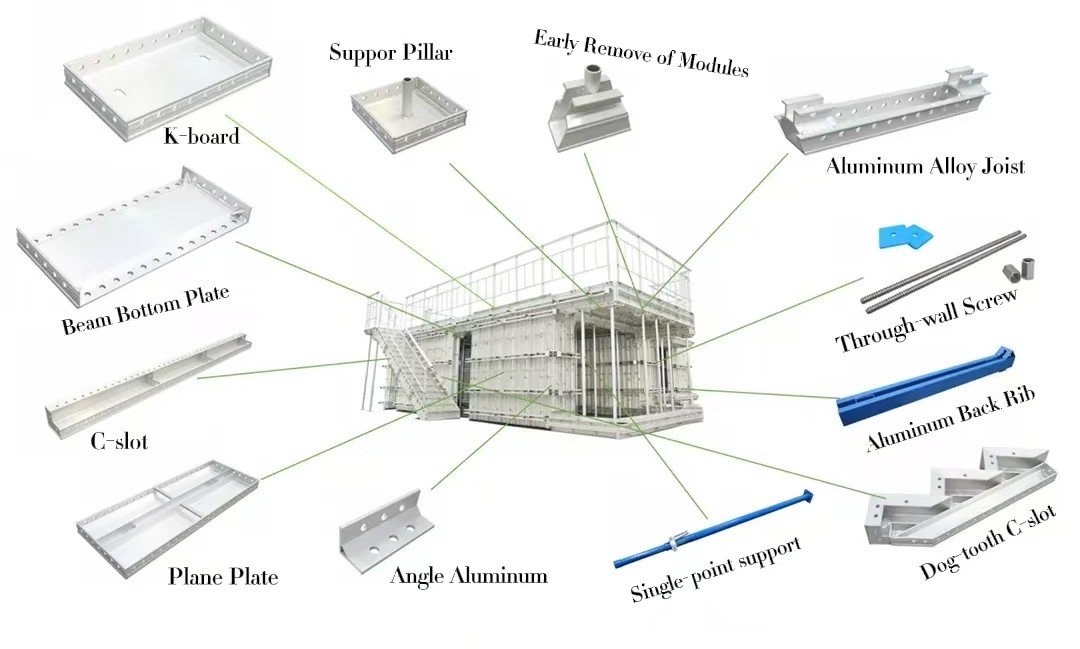

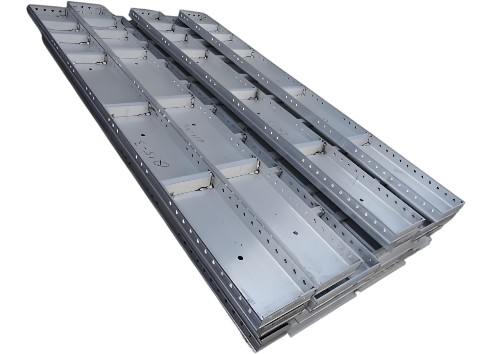

Aluminum formwork is fully called aluminum alloy formwork for concrete project, which is a new type of formwork system. Aluminum formwork is made of aluminum alloy profile as the main material, through machining and welding and other processes, and is suitable for concrete works. It is mainly composed of formwork system, support system, connection system,accessory system and so on.

-

-

PRODUCTS

-

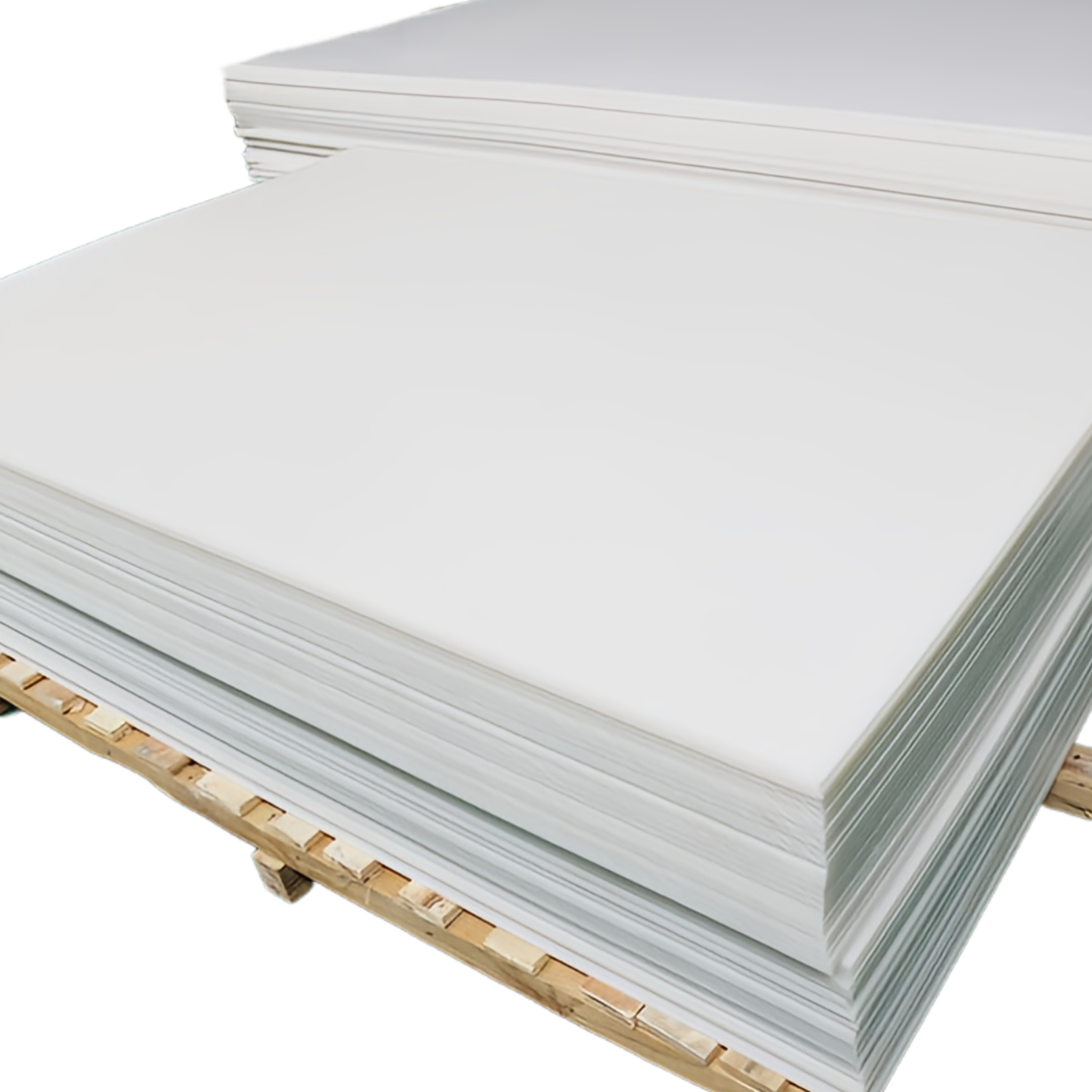

Plastics Sheet

-

High density polyethylene(HDPE)

-

Polybutylene Terephthalate(PBT)

-

Polyetherimide Sheet(PEI )

-

Uhmwpe Sheet(UPE)

-

Polypropylene Board (PP)

-

Polyethylene Board (PE)

-

Polycarbonate Board (PC)

-

Polystyrene Board (PS)

-

Polyvinylchloride Board (PVC)

-

Polyoxymethylene Board (POM)

-

Acrylonitrile-butdiene-styrene Board (ABS)

-

Acrylic Board(PMMA)

-

-

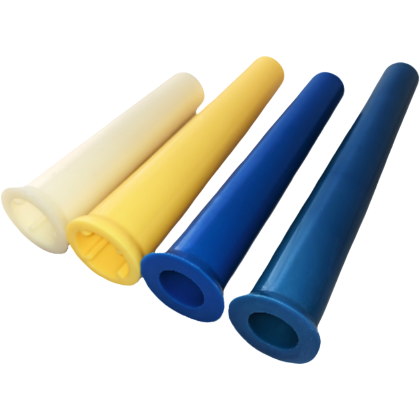

Plastic Rods

-

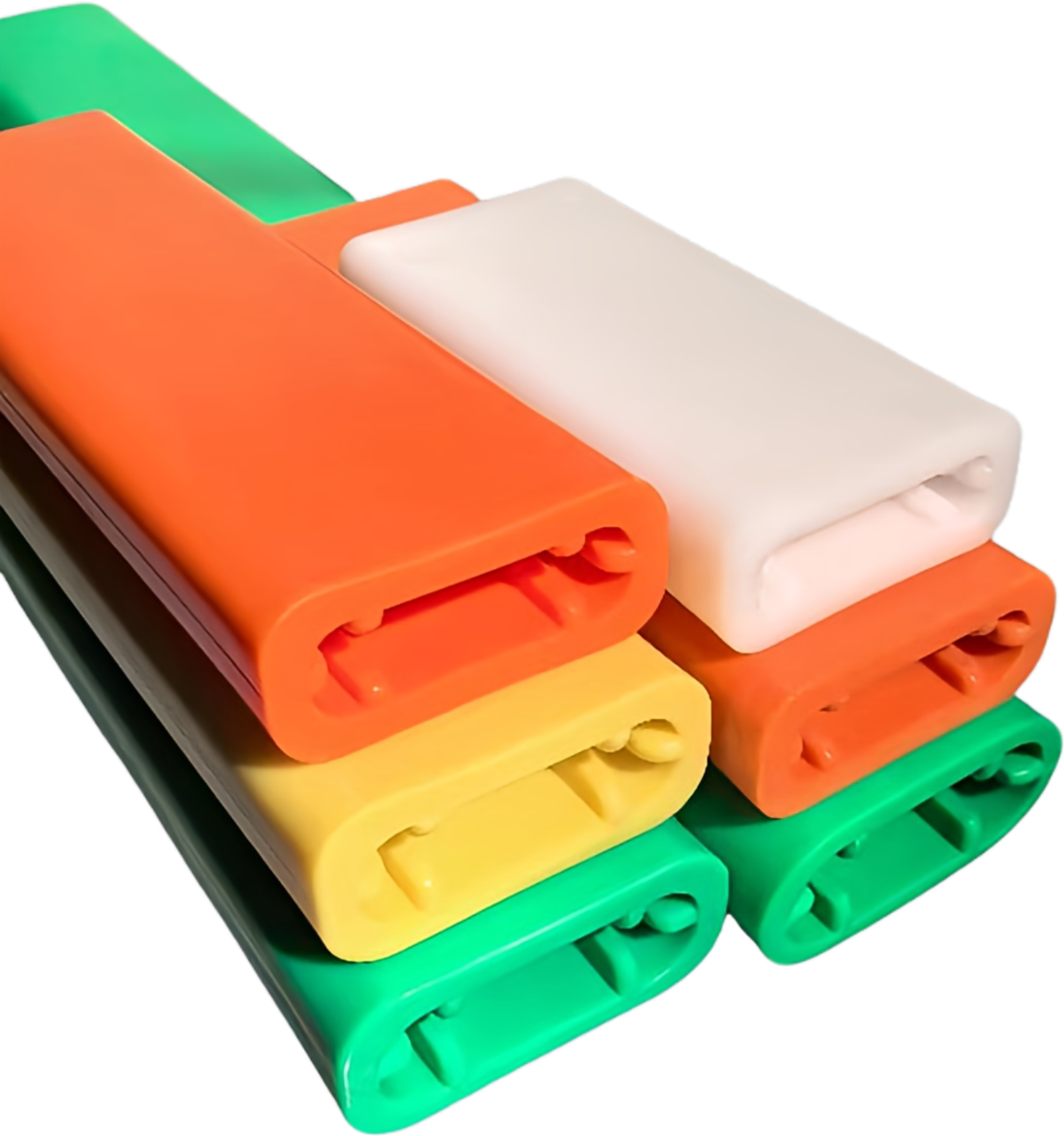

Construction Accessories

-

Aluminum Formwork

-

Refurbished Machine

-

-

SOLUTIONS

-

ABOUT US

-

PARTNERSHIP

-

BLOGS

-